Specialist for the rubber industry, product professional for carbon blacks

Under the brand name LUVOMAXX® we combine a unique range of services for the rubber industry together with our almost 100 years of experience with carbon blacks as a product. Through our worldwide and independent sourcing of raw materials, we offer you economically and technically optimized solutions that we adapt to your processing requirements and produce for you in customized form.

Carbon blacks

LUVOMAXX® BC Tread Grades

| ASTM Test method | N-115 | N-121 | N-134 | N-220 | N-234 | |

|---|---|---|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 113 | 131 | 127 | 114 | 125 |

| Iodine no. (mg/g) | D 1510 | 160 | 121 | 142 | 121 | 120 |

| Ash (% max.) | D 1506 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 500 | 250 | 250 | 250 | 200 |

| Nitrogen surface area (m2/g) | D 6556 | 137 | 122 | 143 | 119 | 119 |

| Appearance | – | black pellets | black pellets | black pellets | black pellets | black pellets |

LUVOMAXX® BC Tread Grades

| ASTM Test method | N-326 | N-330 | N-339 | N-347 | N-375 | |

|---|---|---|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 72 | 102 | 120 | 124 | 114 |

| Iodine no. (mg/g) | D 1510 | 82 | 82 | 90 | 90 | 90 |

| Ash (% max.) | D 1506 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 350 | 200 | 500 | 200 | 250 |

| Nitrogen surface area (m2/g) | D 6556 | 78 | 82 | 90 | 85 | 93 |

| Appearance | – | black pellets | black pellets | black pellets | black pellets | black pellets |

LUVOMAXX® BC Carcass Grades

| ASTM Test method | N-539 | N-550 | N-650 | N-660 | N-772 | |

|---|---|---|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 111 | 121 | 122 | 90 | 65 |

| Iodine no. (mg/g) | D 1510 | 43 | 43 | 36 | 36 | 30 |

| Ash (% max.) | D 1506 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 100 | 200 | 250 | 250 | 500 |

| Nitrogen surface area (m2/g) | D 6556 | 38 | 40 | 36 | 35 | 32 |

| Appearance | – | black pellets | black pellets | black pellets | black pellets | black pellets |

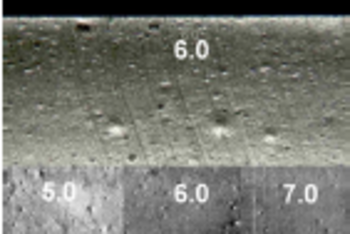

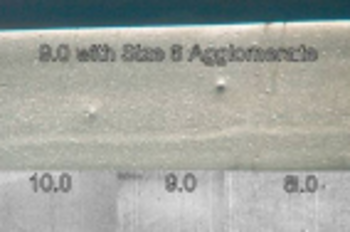

LUVOMAXX® BC "Low-Grit" Grades

| ASTM Test method | N-550 LG | N-650 LG | |

|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 121 | 122 |

| Iodine no. (mg/g) | D 1510 | 43 | 36 |

| Ash (% max.) | D 1506 | 0.5 | 0.5 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 20 | 20 |

| Nitrogen surface area (m2/g) | D 6556 | 40 | 36 |

| Appearance | – | black pellets | black pellets |

LUVOMAXX® Thermal Black Grades

| ASTM Test method | MT N-990 | MT N-991 | |

|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 40 | 40 |

| Iodine no. (mg/g) | D 1510 | 8 | 8 |

| pH value | D 1512 | 9 | 9 |

| Ash (% max.) | D 1506 | 0.1 | 0.1 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 27 | 34 |

| Bulk density (kg/m³) | D 1513 | 500 | 360 |

| Appearance | – | grey-black pellets | grey-black powder |

LUVOMAXX® Lamp Black Grades

| ASTM Test method | LB/P | LB/S | |

|---|---|---|---|

| Oil adsorption (ml/100g) | D 2414 | 100 | 95 |

| Iodine no. (mg/g) | D 1510 | 14 | 30 |

| pH value | D 1512 | 0.5 | 0.5 |

| Ash (% max.) | D 1506 | 0.1 | 0.1 |

| Sieve residue 325 mesh (ppm max.) | D 1514 | 7 | 6 – 11 |

| Bulk density (kg/m³) | D 1513 | 400 | 200 |

| Appearance | – | black pellets | black powder |

Rubber chemicals

Pure substances

| Product | Appearance | Active ingredient | Melting point (onset) |

|---|---|---|---|

| LUVOMAXX® 6PPD | Dark brown granules | N-(1,3-dimethylbutyl)-N’-phenyl-p-phenylenediamine | 50 °C |

| LUVOMAXX® BHT | White powder | 2,6–di-tert-butyl-4-methylphenol | 68 °C |

| LUVOMAXX® BHP | Light yellow powder | 2,2-Methylene-bis-(4-methyl-6-tert-butyl phenol) | 124 °C |

| LUVOMAXX® CDPA | White powder | 4,4'-bis-(1,1-dimethylbenzyl)- diphenylamine | 99 °C |

| LUVOMAXX® DTPD | Brownish flakes | N,N’-ditolyl-p-phenylenediamine | 93 °C |

| LUVOMAXX® IPPD | Dark brown granules | N-isopropyl-N’-phenyl –p-phenylenediamine | 75 °C |

| LUVOMAXX® MBI/OC | Oil-coated powder | 2-Mercaptobenzimidazole | 295 °C |

| LUVOMAXX® MMBI/OC | Oil-coated powder | 4- /5-methyl mercaptobenzimidazole | 270 °C |

| LUVOMAXX® ODPA | Brownish powder | 4,4'-dioctyl diphenylamine | 85 °C |

| LUVOMAXX® SDPA | Highly viscous amber liquid | Styrenated diphenylamine | - 5 °C |

| LUVOMAXX® TMQ | Amber granules | Polymeric 2,2,4-trimethyl-1,2-dihydro-quinoline | 80 °C |

Polymer-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Binder |

|---|---|---|---|---|

| LUVOMAXX® IPPD GR 80 | Granules | N-isopropyl-N’-phenyl-p- phenylenediamine | 80 | EPDM / EVA |

| LUVOMAXX® MBI GR 80 | Granules | 2-Mercapto-benzimidazole | 80 | EPDM / EVA |

| LUVOMAXX® MMBI GR 70 | Granules | 4 / 5-Methylmercapto-benzimidazole | 70 | EPDM / EVA |

Dry liquid preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® SDPA DL 72 C | Beige powder | Styrenated diphenylamine | 72 | Ca silicate |

| LUVOMAXX® TNPP DL 70 | White powder | Tris-(nonylphenyl) phosphite* | 70 | Silica |

* Hydrolysis-protected; content of free 4-nonylphenol < 0.1% - this TNPP grade is no SVHC candidate (status 16.07.2019)

Pure substances

| Product | Appearance | Active ingredient | Colour | Melting point (onset) |

|---|---|---|---|---|

| Sulphenamides | ||||

| LUVOMAXX® CBS | Granules/ oil-coated powder | N-cyclohexyl-2 benzothiazolesulphenamide | Off-white/ greyish | 98 °C |

| LUVOMAXX® DCBS | Granules/ | N,N-dicyclohexyl-2-benzothiazolesulphenamide | Light beige | 96 °C |

| LUVOMAXX® TBBS | Granules/oil-coated powder | N-tert-butyl-2-benzothiazolesulphenamide | Off-white/ greyish | 104 °C |

| LUVOMAXX® TBSI | Oil-coated powder | N-tert-butyl-di(2-benzothiazole) sulphenimide | Off-white to cream | 137 °C |

| Thiazoles | ||||

| LUVOMAXX® MBT | Granules/ oil-coated powder | 2-Mercaptobenzothiazole | Light yellow | 171 °C |

| LUVOMAXX® MBTS | Granules/ oil-coated powder | Dibenzothiazyldisulphide | Pale yellow | 165 °C |

| LUVOMAXX® ZMBT | Granules/oil- coated powder | Zinc salt of 2-mercapto-benzothiazole | Light yellow | 200 °C |

| Dithiocarbamates | ||||

| LUVOMAXX® TDEC | Granules/oil- coated powder | Tellurium diethyl dithiocarbamate | Orange to yellow | 110 °C |

| LUVOMAXX® ZBEC | Granules/oil- coated powder | Zinc dibenzyl dithiocarbamate | White | 180 °C |

| LUVOMAXX® ZDBC | Granules/oil- coated powder | Zinc dibutyl dithiocarbamate | White | 104 °C |

| LUVOMAXX® ZDEC | Granules/oil-coated powder | Zinc diethyl dithiocarbamate | White | 174 °C |

| Guanidines | ||||

| LUVOMAXX® DPG | Granules/ oil coated powder | Diphenylguanidine | Off-white/ greyish | 144 °C |

| Dithiophosphates | ||||

| LUVOMAXX® ZDTP | Viscous liquid | Zinc dialkyl dithiophosphate | Yellowish | -10 °C |

| Thiurams | ||||

| LUVOMAXX® DPTT | Granules/oil- coated powder | Dipentamethylenethiuram tetrasulphide | White to light yellow | 103 °C |

| LUVOMAXX® TBzTD | Granules/oil- coated powder | Tetrabenzylthiuram disulphide | White | 130 °C |

| LUVOMAXX® TETD | Granules/oil- coated powder | Tetraethylthiuram disulphide | Light yellow | 66 °C |

| LUVOMAXX® TiBTD | Granules/oil- coated powder | Tetraisobutylthiuram disulphide | White | 65 °C |

| LUVOMAXX® TMTM | Granules/oil- coated powder | Tetramethylthiuram monosulphide | Yellow | 104 °C |

| Thioureas | ||||

| LUVOMAXX® ETU | Granules/oil- coated powder | N-N'-ethylene thiourea (2-mercaptoimidazoline) | White | 195 °C |

| LUVOMAXX® MTT | Powder | 3-methyl thiazolidine-2-thione | Off-white | 65°C |

| Sulphur donors | ||||

| LUVOMAXX® DTDM | Oil- coated powder | 4,4’-dithiodimorpholine | White | 119 °C |

| Amine Accelerators | ||||

| LUVOMAXX® HMT | Crystal powder | Hexamethylene tetramine | White | > 200°C sublimates |

Polymer-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Binder |

|---|---|---|---|---|

| Sulphenamides | ||||

| LUVOMAXX® CBS GR 80 | Granules | N-cyclohexyl-2 benzothiazyl- sulphenamide | 80 | EPDM / EVA |

| LUVOMAXX® TBBS GR 80 | Granules | N-tert butyl-2-benzothiazyl-sulphenamide | 80 | EPDM / EVA |

| Thiazole | ||||

| LUVOMAXX® MBT GR 80 | Granules | 2-mercaptobenzothiazole | 80 | EPDM / EVA |

| LUVOMAXX® MBTS GR 75 | Granules | Dibenzothiazyldisulphide | 75 | EPDM / EVA |

| LUVOMAXX® ZMBT GR 80 | Granules | Zinc salt of 2-mercaptobenzothiazole | 80 | EPDM / EVA |

| Dithiocarbamate | ||||

| LUVOMAXX® ZDBC GR 80 | Granules | Zinc dibutyl dithiocarbamate | 80 | EPDM / EVA |

| LUVOMAXX® ZDEC GR 80 | Granules | Zinc diethyl dithiocarbamate | 80 | EPDM / EVA |

| LUVOMAXX® ZBEC GR 80 | Granules | Zinc dibenzyl dithiocarbamate | 80 | EPDM / EVA |

| Guanidines | ||||

| LUVOMAXX® DPG GR 80 | Granules | Diphenylguanidine | 80 | EPDM / EVA |

| Dithiophosphates | ||||

| LUVOMAXX® ZDTP GR 50 | Granules | Zinc dialkyl dithiophosphate | 50 | EPDM / EVA |

| Thiurams | ||||

| LUVOMAXX® DPTT GR 70 | Granules | Dipentamethylenethiuram tetrasulphide | 70 | EPDM / EVA |

| LUVOMAXX® TBzTD GR 70 | Granules | Tetrabenzylthiuram disulphide | 70 | EPDM / EVA |

| LUVOMAXX® TMTM GR 80 | Granules | Tetramethylthiuram monosulphide | 80 | EPDM / EVA |

| Thioureas | ||||

| LUVOMAXX® ETU GR 80 | Granules | N-N'- ethylene thiourea | 80 | EPDM / EVA |

| Sulphur donors | ||||

| LUVOMAXX® CLD GR 80 | Granules | Caprolactam disulphide | 80 | EPDM / EVA |

| LUVOMAXX® DTDM GR 70 | Granules | 4,4’-dithiodimorpholine | 70 | EPDM / EVA |

| Amine accelerators | ||||

| LUVOMAXX® HMT GR 80 | Granules | Hexamethylene tetramine | 80 | EPDM / EVA |

Dry liquid preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® AS 100 DL 70 | Pale yellow powder | Diisopropyl xanthogene polysulfide | 70 | silica |

| LUVOMAXX® DBU DL 70* | White powder | Cyclic diamine | 70 | silica |

| LUVOMAXX® ZDTP DL 73 | White powder | Zinc dialkyl dithiophosphate | 73 | silica |

* Possible replacement for guanidine accelerator DOTG

Pure substances

| Product | Appearance | Active ingredient | Purity (% m/m) | Viscosity (mPas) |

|---|---|---|---|---|

| LUVOMAXX® 1,4 BDMA | Clear liquid | 1,4-Butanediol dimethacrylate | 90 | 6.5 |

| LUVOMAXX® EDMA | Clear liquid | 1,2-Ethanediol dimethacrylate | 98 | 6 |

| LUVOMAXX® HMDC OC | White powder | Hexamethylenediamine carbamate | 99 | n.a. |

| LUVOMAXX® TEDMA | Clear liquid | Triethyleneglycol dimethacrylate | 95 | 10.5 |

| LUVOMAXX® TMPT | Clear liquid | Trimethylolpropane trimethacrylate | 90 | 45 |

| LUVOMAXX® TAC | Off-white solid or liquid | Triallylcyanurate | 98 | Solid at room temp. |

| LUVOMAXX® TAIC | Off-white solid or liquid | Triallyl isocyanurate | 98 | Semi-crystalline at room temp. |

Dry liquid preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® BDMA DL 75 C | Light-grey powder | 1,4-Butanediol dimethacrylate | 75 | Ca silicate |

| LUVOMAXX® EDMA DL 70 | White powder | 1,2-Ethanediol dimethacrylate | 70 | Silica |

| LUVOMAXX® EDMA DL 75 C | Light-grey powder | 1,2-Ethanediol dimethacrylate | 75 | Ca silicate |

| LUVOMAXX® TAC DL 50 | White powder | Triallylcyanurate | 50 | Silica |

| LUVOMAXX® TAC DL 70 | White powder | Triallylcyanurate | 70 | Silica |

| LUVOMAXX® TAIC DL 50 | White powder | Triallyl isocyanurate | 50 | Silica |

| LUVOMAXX® TAIC DL 70 | White powder | Triallyl isocyanurate | 70 | Silica |

| LUVOMAXX® TAIC DL 70 C | Light-grey powder | Triallyl isocyanurate | 70 | Ca silicate |

| LUVOMAXX® TMPT DL 70 | White powder | Trimethylolpropane trimethacrylate | 70 | Silica |

| LUVOMAXX® TMPT DL 75 C | Light-grey powder | Trimethylolpropane trimethacrylate | 75 | Ca silicate |

| LUVOMAXX® TMPT SR DRY DL | White powder | Trimethylolpropane trimethacrylate with scorch retarder | 70 | Silica |

Mineral-oil-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® HMDC OC | White powder | Hexamethylenediamine carbamate | 90 | Plasticizer |

| LUVOMAXX® K-CDO 65 | Dark brown paste | 1,4-Quinone dioxime | 65 | Mineral oil |

Polymer-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Binder |

|---|---|---|---|---|

| LUVOMAXX® HMDC GR 70 AEM | Granules | Hexamethylendiamine carbamate | 70 | AEM |

| LUVOMAXX® TAC WB 50 E | Granules | Triallylcyanurate | 50 | EVA with inert mineral additive |

Pure substances

| Product | Appearance | Active ingredient | Total sulphur cont. (%) | Density (g/cm³) | Avg. sulphur chain length |

|---|---|---|---|---|---|

| LUVOMAXX® TESPT | Yellow liquid | Bis-[3-(triethoxysilyl)-propyl]-tetrasulphane | 22.7 | 1.09 | 3.75 |

| LUVOMAXX® TESPD | Yellow liquid | Bis-[3-(triethoxysilyl)-propyl]-disulphane | 14 | Disulphane- Content (mol%): 85 | 2.2 |

| LUVOMAXX® TESPD/B | Yellow liquid | Bis-[3-(triethoxysilyl)-propyl]-disulphane | 15 | 75 | 2.3 |

| Product | Appearance | Active ingredient | Boiling point [°C(hPa)] | Density (g/cm³) |

|---|---|---|---|---|

| LUVOMAXX® Aminosil | Clear liquid | 3-Aminopropyl triethoxy-silane | 69 (4) | 0.96 |

| LUVOMAXX® Aminosil M | Clear liquid | 3-Aminopropyl-trimethoxy-silane | 194 (1013) | 1.02 |

| LUVOMAXX® Aminosil MMO | Clear liquid | 3-Aminopropyl methyl- dimethoxysilane | 200 (1013) | 0.95 |

| LUVOMAXX® Aminosil EDA | Clear liquid | N-(2-Aminoethyl)-3-amino-propyl trimethoxysilane | 147 (16) | 1.02 |

| LUVOMAXX® Mercaptosil | Clear liquid | 3- Mercaptopropyl-trimethoxysilane | 85 (4) | 1.07 |

| LUVOMAXX® Methasil | Clear liquid | 3- Methacryloxypropyl-trimethoxysilane | 205 (1013) | 1.05 |

| LUVOMAXX® Epoxysil | Clear liquid | 3-Glycidyloxypropyl-trimethoxysilane | 90 (1) | 1.06 |

| LUVOMAXX® Octasil | Clear liquid | n-Octyl triethoxysilane | 84 (0.5 mm Hg) | 0.88 |

| LUVOMAXX® Alkylsilan C12 | Clear liquid | n-Dodecyl triethoxysilane | 125 (1.8 mm Hg) | 0.89 |

| LUVOMAXX® OVMS | Clear liquid | Vinyl-functional oligosiloxane | n.a. | 1.0 |

| LUVOMAXX® Vinylosil T 101 | Clear liquid | Vinyl-functional organosilane (VTMOEO) | 110 (3) | 1.03 |

| LUVOMAXX® Vinylosil T 102 | Clear liquid | Vinyl-functional organosilane (VTEO) | 158 (1013) | 0.92 |

| LUVOMAXX® Vinylosil T 103 | Clear liquid | Vinyl-functional organosilane (VTMO) | 123 (1013) | 0.95 |

Dry liquid preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® AMEO DL 70 | White powder | 3-Aminopropyl triethoxysilane | 70 | Silica |

| LUVOMAXX® GLYMO DL 70 | White powder | 3-Glycidyloxypropyl trimethoxysilane | 70 | Silica |

| LUVOMAXX® MTMO DL 70 | White powder | 3-Mercaptopropyl trimethoxysilane | 70 | Silica |

| LUVOMAXX® OVMS DL 70C | Light-grey powder | Vinyl-functional oligosiloxane | 70 | Ca silicate |

| LUVOMAXX® TESPT DL 50/L | White powder | Bis-[3-(triethoxysilyl)-propyl]-tetrasulfane | 50 | Silica (BET: 125m²/g) |

| LUVOMAXX® TESPT DL 70 C | Light yellow powder | Bis-[3-(triethoxysilyl)-propyl]-tetrasulfane | 70 | Ca silicate |

| LUVOMAXX® VTMO DL 70 | White powder | Vinyl trimethoxysilane | 70 | Silica |

| LUVOMAXX® VTMOEO DL 50 C | Light-grey powder | Vinyl-tris-(2-methoxyethoxy)-silane | 50 | Ca silicate |

| LUVOMAXX® VTMOEO DL 70 C | Light-grey powder | Vinyl-tris-(2-methoxyethoxy)-silane | 70 | Ca silicate |

Carbon-black-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® 64B/R | Black pellets | Bis-[3-(triethoxysilyl)-propyl]- disulphane, TESPD / B | 50 | Carbon black N-330 |

| LUVOMAXX® R Si-B | Black pellets | Bis-[3-(triethoxysilyl)-propyl]- tetrasulphane, TESPT | 50 | Carbon black N-330 |

Resin curatives

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® HM3 DL 72 C | Powder | Oligomeric hexamethoxymethylol-melamine | 72 | Ca silicate |

| LUVOMAXX® HMT GR 80 | Granules | Hexamethylene tetramine | 80 | EPDM / EVA |

Pure substances

LUVOMAG® Magnesium Oxide Powders

| Grade LUVOMAG® | Surface Activity BET area [m2/g] | Bulk density [g/l] | Particle size d50 [µm] | Purity MgO content* | |

|---|---|---|---|---|---|

| High activity grades | M 175 | 185 | 500 | 2 | > 99,2 % |

| M 074 | 160 | 400 | 3 | > 98,7 % | |

| N50® | 140 | 230 | 3 | > 97,7 % | |

| N50® / light | 140 | 205 | 3 | > 97,7 % | |

| M 474 | 140 | 350 | 3 | > 97,5 % | |

| Medium activity grades | M 072 | 100 | 395 | 3 | > 98,5 % |

| M 440 | 50 | 200 | 3 | > 98,0 % | |

| Low activity grades | M 045 | 45 | 350 | 6 | > 98,5 % |

| M H30 light | 40 | 220 | 3 | > 97,8 % | |

*weight% on ignited basis

You can find an overview of our entire range of magnesium oxides here.

Other metal oxides

| Grade | Appearance | Description | Content min (%) | BET surface area (m²/g) | Density (g/cm3) |

|---|---|---|---|---|---|

| LUVOMAXX® ZnO BP | White powder | High purity zinc oxide; vulcanization activator | 99.9 | 6 | 5.6 |

| ZINKWEISS HANSA ULTRA | White powder | High purity zinc oxide; vulcanization activator | 99.8 | 9 | 5.5 |

Polymer-bound preparations

| Grade | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® ZnO GR 80 | Granules | High-purity zinc oxide (ZnO) | 80 | EPDM / EVA |

Oil-bound preparations

High activity magnesium oxide is finely dispersed in a non-migrating, organic binder system. Due to its hydrophobic nature, the binder prevents MgO aging from moisture uptake and CO2 absorbtion.

| Grade LUVOMAG® | MgO content [wt %] | Particle size d50 [µm] | Bulk density [g/l] | |

|---|---|---|---|---|

| Based on high activity grades | 300 | 60 | 3 | 1,900 |

| Based on medium activity grades | 270 | 70 | 8 | 1,900 |

| 290 | 75 | 8 | 1,900 | |

| 280 | 80 | 8 | 1,900 | |

| Grade | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® ZnO EXTRA | Light-grey bars | Zinc oxide (ZnO) | 88 | Emulsifying plasticizer |

Dry liquid preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® ODOR C DL70 | White powder | Cherry-odorant | 70 | Silica |

| LUVOMAXX® ODOR R/3 | White powder | Reactive odorant, mercaptane scavenger | 70 | Silica |

| LUVOMAXX® ODOR V DL 70 | White powder | Vanilla-odorant | 70 | Silica |

Dry liquid preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® FH DL 72 | Light yellow powder | Aromatic polyether (xylene-formaldehyde condensate) | 72 | Silica |

| LUVOMAXX® LNBR 1312 DL 72 | Light -grey powder | Liquid NBR-rubber with 28% rel. ACN content | 72 | Silica |

| LUVOMAXX® KSA DL 70 C | Light -grey powder | Polyethylene glycol, silica activator | 70 | Ca silicate |

| LUVOMAXX® TM DL 70 | White powder | Trialky trimellitate (C7 - C9) | 70 | Silica |

| LUVOMAXX® TP 90 B DL 72 C | Light -grey powder | Hexaoxatricosane, oligoether | 72 | Ca silicate |

| LUVOMAXX® N DL 70 | Brownish powder | Dimethylnaphtalene-tetramer | 70 | Silica |

Pure substances

| Product | Appearance | Active ingredient | Gas yield (ml/g) | Decomp. temperature (°C) |

|---|---|---|---|---|

| LUVOPOR® ABF/70 P-FF | Yellow powder | Azodicarbonamide, avg. ps 4 μm | 220 | 200 |

| LUVOPOR® OB Pulver | White powder | 4,4’-Oxybis (benzene sulphonylhydrazide) | 150 | 160 |

| LUVOMAXX® OBSH 3 | White powder | 4,4’-Oxybis (benzene sulphonylhydrazide) | 150 | 160 |

| LUVOPOR® TSH Pulver | White powder | Toluene sulphonylhydrazide | 115 | 135 |

Powder blends

| Product | Appearance | Active ingredient | Gas yield (ml/g) | Decomp. temperature (°C) |

|---|---|---|---|---|

| LUVOPOR® AT 6100 | Yellow powder | System, based on azodicarbonamide | 280 | 150 |

| LUVOPOR® 9509 | Yellow powder | ZnO-activated azodicarbonamide | 165 | 190 |

Polymer-bound preparations

| Product | Appearance | Active ingredient | Gas yield (ml/g) | Decomp. temperature (°C) | Carrier |

|---|---|---|---|---|---|

| LUVOMAXX® AZ GR | Yellow granules | Azodicarbonamide (75%) | 220 | 200 | EPM |

| LUVOMAXX® OB GR | White granules | 4,4’-Oxybis (benzene sulfonyl- hydrazide) (75%) | 100 | 160 | EPM |

Mineral-oil-bound preparations

| Product | Appearance | Active ingredient | Gas yield (ml/g) | Decomp. temperature (°C) | Carrier |

|---|---|---|---|---|---|

| LUVOPOR® AT 6180 | Yellow powder | Azodicarbonamide and toluene sulphonyl hydrazide, 80% | 170 | 150 | Mineral oil |

| LUVOPOR® OB - Paste 80% | White powder | 4,4’-Oxybis(benzene- sulphonylhydrazide), 80% | 125 | 150 | Mineral oil |

| LUVOMAXX® OBSH OC 80 | White powder | 4,4'-Oxybis(benzol- sulphohydrazide), 80% | 125 | 150 | Mineral oil |

| LUVOPOR® TSH-Paste | White powder | Toluene sulphonylhydrazide, 75% | 110 | 140 | Mineral oil |

| LUVOPOR® 9259 | Light yellow powder | Exothermic/endothermic blowing agent system, 80 % | 165 | 135 | Mineral oil |

| LUVOPOR® 9326 | Yellow powder | Azodicarbonamide, 95% | 280 | 200 | Mineral oil |

| LUVOPOR® 9353 | Yellow powder | Modified azodicarbonamide, 75.5% | 210 | 200 | Mineral oil |

| LUVOPOR® 9382 | Yellow powder | Azodicarbonamide, 80% | 240 | 195 | Mineral oil |

Epoxy resins

Dry liquid preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® LER 828 DL 60 | Off-white powder | Liquid epoxy resin Epikote 828 curing agent for ACM, CSM | 60 | Silica |

Sulphurs

Polymer-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® S GR 80 | Granules | Soluble sulphur | 80 | EPDM / EVA |

| LUVOMAXX® S-IS GR 75 | Granules | Blend of insoluble sulphur and soluble sulphur | 75 | EPDM / EVA |

Mineral-oil-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Binder |

|---|---|---|---|---|

| LUVOMAXX® IS OC 80 | Powder | Insoluble sulphur | 80 | Naphthenic oil |

| LUVOMAXX® IS OC 90 | Powder | Insoluble sulphur | 90 | Naphthenic oil |

Pure substances

| Product | Appearance | Active ingredient | Melting point, onset (°C) |

|---|---|---|---|

| LUVOMAXX® BSA | Off-white powder | N-phenyl-N-(trichloromethyl-sulfenyl)- benzene sulphonamide | 105 |

| LUVOMAXX® CTPI | White powder | N-cyclohexyl thiophthalimide | 90 |

| LUVOMAXX® CTPI Pellets | White granules | N-cyclohexyl thiophthalimide | 90 |

| LUVOMAXX® PSA - F | White flakes | Phthalic acid anhydride | 130 |

| LUVOMAXX® SA | White powder | Salicylic acid anhydride | 158 |

Polymer-bound preparations

| Product | Appearance | Active ingredient | Content (% m/m) | Carrier |

|---|---|---|---|---|

| LUVOMAXX® CTPI GR 80 | Granules | N-cyclohexyl thiophthalimide | 80 | EPDM / EVA |

| LUVOMAXX® BSA GR 80 | Granules | N-phenyl-N-(trichloromethyl-sulphenyl)- benzene sulphonamide | 80 | EPDM / EVA |

Synthetic rubber

| Emulsion Styrene Butadiene Rubber (SBR) | Grade | Styrene (%) | Viscosity ML (1+4) 100°C | Oil Content phr |

|---|---|---|---|---|

| E-SBR | 1500 | 23,5 | 52 | - |

| E-SBR | 1502 | 23,5 | 52 | - |

| E-SBR | 1502 F | 23,5 | 52 | - |

| E-SBR | 1509 | 23,5 | 33 | - |

| E-SBR | 1721 | 40 | 54 | 37,5 DAE |

| E-SBR | 1723 | 23,5 | 48 | 37,5 TDAE |

| E-SBR | 1739 | 40 | 52 | 37,5 TDAE |

| E-SBR | 1778 | 23,5 | 49 | 37,5 NAPH |

| HSR | HS 630 | 63 | 56 | - |

| Solution Styrene Butadiene Rubber (SSBR) | Grade | Styrene (%) | Vinyl (%) | Viscosity ML (1+4) 100°C | Oil Content phr |

|---|---|---|---|---|---|

| S-SBR | SOL 1205 | 25 | 53 | - | |

| S-SBR | SOL R72606 | 25 | 67 | 45 | 37,5 DAE |

| S-SBR | SOL R72612 | 25 | 67 | 48 | 36,8 MES |

| S-SBR | SOL R72613 | 25 | 64 | 60 | - |

| S-SBR | SOL 72614 | 25 | 64 | 55 | 37,5 TDAE |

| S-SBR | SOL R2525 | 26 | 24 | 52 | - |

| High Cis | Cis (%) | Viscosity ML (1+4) 100°C |

|---|---|---|

| NEOCIS BR 40 | 98 | 43 |

| NEOCIS BR 60 | 98 | 63 |

| Low Cis | Cis (%) | Viscosity ML (1+4) 100°C |

|---|---|---|

| INTENE 50 | 38 | 48 |

| High Vinyl | Vinyl (%) | Viscosity ML (1+4) 100°C |

|---|---|---|

| EUROPRENE BR HV80 | 80 | 70 |

| Styrene-Butadiene (SBS) | Structure | Styrene (%) | Diblock (% wt) |

|---|---|---|---|

| SBS EUROPRENE SOL T 166 | Linear | 30 | 10 |

| SBS EUROPRENE SOL T 6205 | Radial | 25 | 10 |

| SBS EUROPRENE SOL T 6302 | Linear | 30 | 12 |

| SBS EUROPRENE SOL T 6320 | Linear | 31 | 75 |

| SBS EUROPRENE SOL T 6414 | Radial | 40 | 22 |

| Styrene-Isoprene (SIS) | Structure | Styrene (%) | Diblock (% wt) |

|---|---|---|---|

| SIS EUROPRENE SOL T 190 | Linear | 16 | 25 |

| SIS EUROPRENE SOL T 9113 | Linear | 18 | 8 |

| SIS EUROPRENE SOL T 9131 | Linear | 15 | 40 |

| SIS EUROPRENE SOL T 9133 | Linear | 16 | 55 |

| SIS EUROPRENE SOL T 9326 | Linear | 30 | 15 |

| Styrene-Ethylene-Butylene (SEBS) | Structure | Styrene (%) | Diblock (% wt) |

|---|---|---|---|

| SEBS EUROPRENE SOL T 2311 | Linear | 30 | - |

| SEBS EUROPRENE SOL T 2312 | Linear | 30 | - |

| SEBS EUROPRENE SOL T 2314 | Linear | 31 | - |

| SEBS EUROPRENE SOL T 2315 | Linear | 32 | - |

| Propylene Content (% wt) | Viscosity Mooney ML (1+4) 125°C | Oil Content (% wt) | |

|---|---|---|---|

| DUTRAL CO 034 | 28 | 44 | - |

| DUTRAL CO 038 | 28 | 60 | - |

| DUTRAL CO 043 | 45 | 33 | - |

| DUTRAL CO 054 | 41 | 44 | - |

| DUTRAL CO 058 | 48 | 80 | - |

| DUTRAL CO 059 | 41 | 79 | - |

| Terpolymer | Propylene Content (% wt) | Viscosity Mooney ML (1+4) 125°C | Oil Content (% wt) | ENB (%) |

|---|---|---|---|---|

| DUTRAL TER 4033 | 25 | 30 | - | 5 |

| DUTRAL TER 4038 EP | 27 | 60 | - | 4,4 |

| DUTRAL TER 4039 | 27 | 77 | - | 4,4 |

| DUTRAL TER 4044 | 35 | 44 | - | 4 |

| DUTRAL TER 4047 | 40 | 55 | - | 4,5 |

| DUTRAL TER 4049 | 40 | 76 | - | 4,5 |

| DUTRAL TER 4334 | 27 | 28 | 30 | 4,7 |

| DUTRAL TER 4436 | 28 | 43 | 40 | 5,5 |

| DUTRAL TER 4437 | 32 | 57 | 40 | 4,5 |

| DUTRAL TER 4437 WO | 32 | 57 | 40 | 4,5 |

| DUTRAL TER 4535 | 32 | 32 | 50 | 3,4 |

| DUTRAL TER 6148 | 40 | 65 | 15 | 7 |

| DUTRAL TER 6235 | 32 | 33 | 23 | 7,4 |

| DUTRAL TER 6537 | 32 | 43 | 50 | 8 |

| DUTRAL TER 9046 | 31 | 67 | - | 8,9 |

| New grades | Propylene Content (% wt) | Viscosity Mooney ML (1+4) 125°C | Oil Content (% wt) | ENB (%) |

|---|---|---|---|---|

| DUTRAL TX 1301 (TER 4548) | 36 | 47 | 50 | 4,5 |

| DUTRAL TX 1401 (TER 8148) | 39 | 68 | 17,5 | 8,5 |

| DUTRAL TX 1501 (TER 7040) | 40 | 87 | - | 6,5 |

| DUTRAL TX 1502 (BTR 4049) | 40 | 76 | - | 4,5 |

| Standard | ACN (%) | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| EUROPRENE N 2845 | 28 | 45 |

| EUROPRENE N 2860 | 28 | 60 |

| EUROPRENE N 3330 | 33 | 30 |

| EUROPRENE N 3345 | 33 | 45 |

| EUROPRENE N 3360 | 33 | 60 |

| EUROPRENE N 3380 | 33 | 80 |

| EUROPRENE N 3945 | 39 | 45 |

| EUROPRENE N 3960 | 39 | 60 |

| EUROPRENE N 3980 | 39 | 80 |

| EUROPRENE N 4560 | 45 | 60 |

| Green | ACN (%) | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| EUROPRENE N 1934 GRN | 19 | 45 |

| EUROPRENE N 2830 GRN | 28 | 30 |

| EUROPRENE N 2845 GRN | 28 | 45 |

| EUROPRENE N 2860 GRN | 28 | 60 |

| EUROPRENE N 3330 GRN | 33 | 30 |

| EUROPRENE N 3345 GRN | 33 | 45 |

| EUROPRENE N 3380 GRN | 33 | 80 |

| EUROPRENE N 3945 GRN | 39 | 45 |

| NBR-PVC | ACN (%) | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| EUROPRENE N OZO 7028 | 19,5 | 75 |

| EUROPRENE N OZO 7028/60 | 19,5 | 60 |

| EUROPRENE N OZO 7033 | 23 | 75 |

| EUROPRENE N OZO 7033/60 | 23 | 60 |

| EUROPRENE N OZO 7039 | 27 | 75 |

| EUROPRENE N OZO 7045 | 31,5 | 95 |

| EUROPRENE N OZO 5033 | 16,5 | 70 |

| Polyisoprene (IR) | Tg | Viscosity Mooney ML (1+4) 100°C |

|---|---|---|

| ISOGRIP (60% 3,4 - IR) | -11°C | 70 |

| Product | Appearance | Properties and applications | Chlorine content (%) | Mooney ML (1+4) @ 125°C |

|---|---|---|---|---|

| CPE 6035 | White powder | High molecular weight, for applications with requirements on mechanical properties | 34 – 36 | 80 – 105 |

| CPE 6135 | White powder | Medium molecular weight, mainly for cable applications | 34 – 36 | 65 – 72 |

| CPE 6235 | White powder | Medium molecular weight, suitable for good surface quality and high extrusion speed, hoses and cables | 34 – 36 | 70 – 80 |

| CPE 6335 | White powder | Lower molecular weight, easy processing, for applications without high requirements on mechanical properties | 34 – 36 | 45 – 65 |

| CPE 6140 | White powder | Especially suitable for applications that require high oil- and flame resistance, e.g. mining cables | 39 – 41 | 70 – 90 |

| CPE 6240 | White powder | Easy processing and good compatibility with other materials | 39 – 41 | 50 – 80 |

| CPE 4135 | White powder | Suitable for high mechanical requirements | 34 – 36 | 85 – 100 |

| Product | Appearance | Properties and applications | Chlorine content (%) | Shore hardness A |

|---|---|---|---|---|

| CPE 3135 | White powder | Pipes, profiles, sheets made of rigid PVC and other polymers | 34 – 36 | < 65 |

| CPE 7130 | White powder | Especially for magnetic applications, for high dosage levels of magnetic powders | 29 – 31 | < 70 |

| CPE 5236 | White powder | Suited for TPE and soft PVC, good surface quality | 35 – 37 | < 60 |

| CPE 2135 | White powder | Especially for flame retardant ABS | 34 – 36 | < 75 |

| Product | Appearance | Properties and applications | Chlorine content (%) | Sulphur content (%) | Mooney ML (1+4) @ 100°C |

|---|---|---|---|---|---|

| CSM 20 | Off-white irregular chips | Very good resistance to ozone, weathering, oil and chemicals; good low-temperature flexibility; rubber cements, adhesives, tapes, coatings | 27 – 31 | 1.3 – 1.7 | 23 – 33 |

| CSM 30 | Off-white irregular chips | CSM grade with highest chlorine content; predestined for oil contact and flame retardant applications: anti-corrosion coattings, wires and cables, tubes, membranes | 41 – 45 | 0.8 – 1.2 | 35 – 45 |

| CSM 40 (3304) | Off-white irregular chips | Low-viscosity type of standard grade CSM 40; pls. see below | 33 – 37 | 0.8 – 1.2 | 40 – 49 |

| CSM 40 (3305) | Off-white irregular chips | General purpose grade CSM 40, good all-round properties reg. resistance to ozone, weathering, oil and chemicals; tubes, oil-seals, roll coverings, modification of other elastomers | 33 – 37 | 0.8 – 1.2 | 50 – 60 |

| CSM 45 | Off-white irregular chips | Good abrasion resistance, very good weathering and heat resistance, moderate oil resistance; roofings, floorings, magnetic rubber parts, radiation shieldings | 22 – 25 | 0.8 – 1.2 | 32 – 42 |

| CSM 4085 | Off-white irregular chips | High–mw CSM-Type 4085 suited for highly filled compounds; tubes, automotive hoses, seals / articles in contact with oil, cable sheathings, roll coverings | 34 – 38 | 0.8 – 1.2 | 85 – 95 |

| Product | Appearance | Properties and applications | Volatile matter (%) | TG | Mooney ML (1+4) @ 100°C |

|---|---|---|---|---|---|

| ISOGRIP™ | Bales |

| < 0.5 | - 10 °C | 65 – 75 |

DAWNPRENE™ thermoplastic vulcanizates

Injection moulding grades

| Product | Appearance | Density (g/cm3) | Tensile strength (MPa) | Elong. at break (%) | Shore hardn. 10s,23°C | Tear str. (kN/m) | Comp. set 22h@70°C (%) |

|---|---|---|---|---|---|---|---|

| TPV 10-45A | black granules | 0.95 | 4.2 | 450 | 45 (A) | 20 | 38 |

| TPV 10-80A | black granules | 0.97 | 7.5 | 450 | 83 (A) | 42 | 40 |

| TPV 11-73A | black granules | 0.96 | 7.5 | 400 | 74 (A) | 36 | 35 |

| TPV 11-80A | black granules | 0.96 | 11.1 | 550 | 82 (A) | 40 | 33 |

| TPV 11-50D | black granules | 0.93 | 24 | 700 | 50 (D) | 113 | n.a. |

| ASTM D-792 | ASTM D-412 | ASTM D-412 | ASTM D-2240 | ASTM D-624 | ASTM D-395 |

Sealing and profile grades

| Product | Appearance | Density (g/cm3) | Tensile strength (MPa) | Elong. at break (%) | Shore hardn. 10s,23°C | Tear str. (kN/m) | Comp. set 22h@70°C (%) |

|---|---|---|---|---|---|---|---|

| TPV 14-50A | black granules | 0.93 | 4.5 | 600 | 55 (A) | 25 | 25 |

| TPV 10-60A | black granules | 0.97 | 5.3 | 400 | 63 (A) | 27 | 28 |

| TPV T18-75A | black granules | 0.90 | 8.1 | 600 | 75 (A) | 46 | 45 |

| ASTM D-792 | ASTM D-412 | ASTM D-412 | ASTM D-2240 | ASTM D-624 | ASTM D-395 |

Wire and cable grades

| Product | Appearance | Density (g/cm3) | Tensile Strength (MPa) | Elong. at Break (%) | Shore hardn. 10s,23°C | Tear str. (kN/m) | Comp. set 22h@70°C (%) |

|---|---|---|---|---|---|---|---|

| TPV H721-70A | black granules | 0.97 | 7.5 | 550 | 70 (A) | 40 | 30 |

| TPV 12-80A | black granules | 1.21 | 7.3 | 450 | 83 (A) | 42 | 45 |

| TPV 721-93A | black granules | 0.96 | 13 | 600 | 93 (A) | 65 | 50 |

| ASTM D-792 | ASTM D-412 | ASTM D-412 | ASTM D-2240 | ASTM D-624 | ASTM D-395 |

Automotive ventilation pipes, dust caps

| Product | Appearance | Density (g/cm3) | Tensile strength (MPa) | Elong. at break (%) | Shore hardn. 10s,23°C | Tear str. (kN/m) | Comp. set 22h@70°C (%) |

|---|---|---|---|---|---|---|---|

| TPV H721-70A | black granules | 0.93 | 6.3 | 600 | 54 (A) | 29 | 29 |

| TPV 12-80A | black granules | 0.95 | 13.7 | 622 | 90 (A) | 93 | 46 |

| TPV 721-93A | black granules | 0.95 | 22.3 | 830 | 48 (D) | 138 | 60 |

| ASTM D-792 | ASTM D-412 | ASTM D-412 | ASTM D-2240 | ASTM D-624 | ASTM D-395 |

Deformation joints, shims, spacers

| Product | Appearance | Density (g/cm3) | Tensile strength (MPa) | Elong. at break (%) | Shore hardn. 10s,23°C | Tear str. (kN/m) | Comp. set 22h@70°C (%) |

|---|---|---|---|---|---|---|---|

| TPV 11-64A | black granules | 0.97 | 6.6 | 554 | 64 (A) | 22 | 21 |

| TPV 810-80A | black granules | 0.97 | 10.2 | 578 | 83 (A) | 53 | 38 |

| TPV 814-40D | black granules | 0.97 | 13.5 | 684 | 41 (D) | 109 | 30 |

| ASTM D-792 | ASTM D-412 | ASTM D-412 | ASTM D-2240 | ASTM D-624 | ASTM D-395 |

Automotive parts, moulded goods

| Product | Appearance | Density (g/cm3) | Tensile strength (MPa) | Elong. at break (%) | Shore hardn. 10s,23°C | Tear str. (kN/m) | Applications |

|---|---|---|---|---|---|---|---|

| TPV 830-62A | black granules | 0.93 | 5.5 | 450 | 58 (A) | 25 | covers |

| TPV 10-35D | black granules | 0.95 | 15.1 | 634 | 36 (D) | 91 | side airbags |

| TPV 14-40D | black granules | 0.94 | 15 | 580 | 42 (D) | 96 | hub caps |

| ASTM D-792 | ASTM D-412 | ASTM D-412 | ASTM D-2240 | ASTM D-624 | – |

Functional fillers

MISTRON© Talc Series - a functional mineral for rubber

MISTRON© Talc Series products are functional minerals, not simple fillers.

MISTRON© VAPOR products provide the rubber formulator with flexibility to balance the benefits of improved processability with higher product performance. MISTRON© VAPOR products occupy a unique position in the rubber industry and have been used succesfully for more than 50 years.

MISTRON© VAPOR Talc Series - improve your mechanical properties!

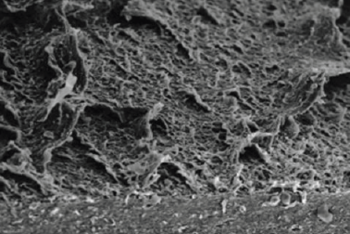

MISTRON© VAPOR is an ultra-fine, micro-lamellar, highly pure, hydreated magnesium silicate specifically developed for the rubber industry. Its platy morphology, organophilic nature, high aspect ratio and surface area result in superior reinforcement and rheology plus permeability resistance for thermoset rubbers.

MISTRON© VAPOR is an extremly soft mineral with a Mohs hardness of one. This property reduces wear on processing equipment compared with other minerals. MISTRON© VAPOR has less than 0.2% absorbed water, which eliminates pre-drying and allows it to be used in liquid-medium cure systems without encountering porosity problems. MISTRON© VAPOR is an electrical insulator and chemically resistant mineral eliminating electrochemical degradation in window seals and hoses plus providing solutions in wire and cable.

MISTRON© VAPOR functions as ...

... Processing Aid providing ...

- Reduced Mixing Times

- Lower Compound Viscosities

- Reduced Heat Generation

- Superior Compound Flow

- Improved Extrusion Rate and Quality

- Better Dispersion of Reinforcing Fillers

- Reduced Elasticity / Nerve

- Higher Green Strength

.. Reinforcement improving ...

- Tensile Properties

- Tear Properties

- Fatigue Performance

- Flaw Resistance

- Improved Thermal Performance

- Superior Weathering

... Improvement for wire and cable

- Chemical and Electrochemical Resistance

- Electrical Insulating Properties

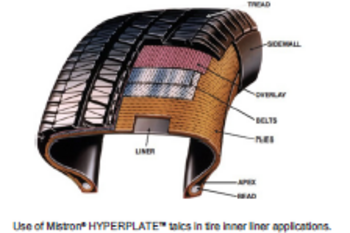

MISTRON© HYPERPLATE™ Speciality talc

New Innovative MISTRON© HYPERPLATE™ ULTRA for Superior Barrier Performance

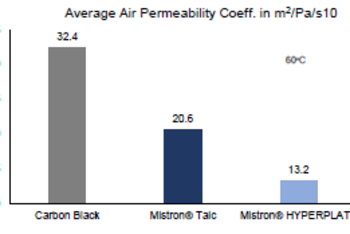

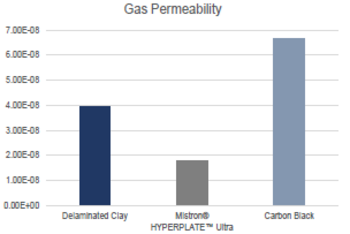

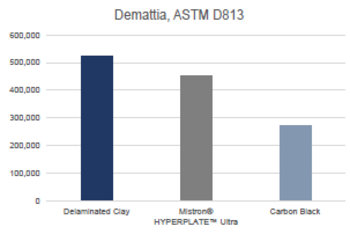

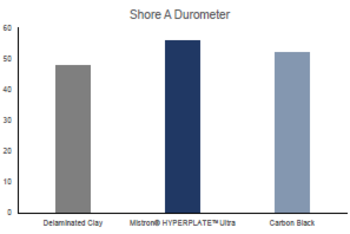

MAGRIS TALC has recently developed a higher aspect ratio HYPERPLATE™ talc for superior barrier performance. In extensive studies multiple talc grades has been tested and MISTRON© HYPERPLATE™ ULTRA was found to be the best performer in Gas Permeability (ASTM D1434) and DeMattia Flex Crack (ASTM D813) against the most commonly used Carbon Black Control and Clay. MISTRON© HYPERPLATE™ ULTRA's gas permeability is 3 times lowerand also sustained about twice the amount of DeMattia Flex Cycles when compared to the Carbon Black Control.

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| SILVERLINE© 002 | Natural white powder, bags | Dusting, relase agent talc | Excellent partioning low cost agents | 8,4 | 55 | 75 |

| VERTAL© 92 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 17,5 | 45 | Y72 |

| VERTAL© 97 | Natural white powder, bags | Dusting | Powdering, cable layer insulation | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (powder) | Natural white powder, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR R (compacted) | White powder compacted, bags | Non-black compounds, EPDM roofing, MRG, hoses, weather stripping | Processability, reinforcement, durability and toughness | 2,2 | 31 | 86 |

| MISTRON© VAPOR RE | Natural white powder, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness | 2,2 | 31 | 80 |

| MISTRON© VAPOR ULTRA | Natural white powder very fine, bags | Black compounds, window seals, MRG | Processability, reinforcement, durability and toughness. Improve extrudate surface quality, enhanced elongation at break | 2 | 12 | 88 |

| MISTRON© CB* | Surface treated powder, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2,2 | 31 | 86 |

| MISTRON© CB6* | Surface treated and finer and densified, bags | Medical stopper, MRG, hoses, seals and gaskets, printed circuit boards | High modulus and good compression set | 2 | 25 | 88 |

| MISTRON© HYPERPLATETM | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,2 | 8 | 80 |

| MISTRON© HYPERPLATETM ULTRA | Delaminated talc, extreme lamellar, bags | Tire inner liners automotive, fuel and hydraulic hoses | Superior permeability resistance, flex fatigue, long life, fire retardancy | 1,5 | 10 | 83 |

| MISTROFOAM©* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, foamed polymer products | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2,2 | 31 | 82 |

| MISTRON© ZSC* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance, higher dielectrical stregths, properties in wire and cable | 2 | 25 | 87 |

| MISTRON© TZ2* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, Improved water resistance and electrical properties in wire and cable | 2 | 25 | 87 |

| MISTROPHOBE* | Surface treated, bags | Wire and cable insulation, MRG, hoses, seals, gaskets | High modulus and good compression set, reaktive chemistry with any unsaturated cure system, that enhances hydrophobicity, wet electrical performance and mechanical properties | 2 | 25 | 88 |

* = surface treated

UPM BioMotion™ are wood-based renewable functional fillers from UPM Biochemicals for innovative and sustainable solutions in the chemical industry.

Given the urgent need to reduce CO2 emissions from rubber products, they offer a sustainable alternative to replace the two dominant fossil-based fillers in rubber products - carbon black and precipitated silica.

The Portfolio is based on biochemicals produced from certified sustainable and regional hardwood and sawmill waste in a biorefinery in Leuna.

The UPM BioMotion™ products can make a significant contribution to improving the sustainability of end-use applications in the rubber industry, in particular through weight reduction and significantly lower CO2 emissions. The functional fillers are mainly used in elastomers, which are used in various applications including the automotive industry, floor coverings and shoe soles.

The production process is patent-protected and unique worldwide.

In addition to the improved carbon footprint, UPM BioMotion™ products also have greater purity. Furthermore, they enable a weight saving of up to 25 percent in rubber applications compared to fillers based on fossil raw materials. For the automotive industry in particular, weight savings mean higher mileage, lower costs and an additional reduction in CO2 emissions.

Only recently, the European Rubber Journal ranked these products number four in the top 10 projects for new, sustainable elastomers. Furthermore, UPM Biochemicals' investment in the biorefinery in Leuna has made it to the finalists in the competition for the German Corporate Sustainability Award 2022 and has been shortlisted for Chemical Week's Sustainability Awards.

Based on its specific surface area ranging from 10 m²/g – 40 m²/g, they fall into the category of semi-reinforcing functional fillers. Due to the polar nature of its surface, RFFs show a strong interaction and reinforcement in polar rubbers, like NBR, AEM, ACM, and FKM. In non-polar rubbers, like EPDM, SBR, or NR, typically lower levels of reinforcement are achieved in direct comparison to traditional functional fillers with similar specific surface areas

Currently, there are three grades to offer with a different specific surface area between 10m2/g and 40m2/g. There is ongoing development to expand the product range shortly

They are available in pellet (granulate) format. They should be stored in a clean, dry space away from exposure to high temperatures, open flames. Pelletized Grades are much easier to handle due to significantly better flow and conveying properties. They would be commercially available in big bags (2m3) and low melting PE bags (EVA) ranging from 5kg to 20kg.

| UPM BioMotionTM | X10 | X20 | X30 |

|---|---|---|---|

| STSA Surface Area [m2/g] | 11 | 23 | 40 |

| pH | 6 - 10 | 6 - 10 | 6 - 10 |

| Sulfur Content [%[ | < 0.2 | < 0.2 | < 0.2 |

| Benzo[a]pyrene [ppm] | < 0.1 | < 0.1 | < 0.1 |

| Each of 22 FDA PAHs [ppm] | < 1 | < 1 | < 1 |

| Loss on Drying [%] | < 3 | < 3 | < 3 |

| Product | Appearance | Description | C-Content (%) | OAN (ml/100g) | Density (g/cm³) | Average particle size* (μm) |

|---|---|---|---|---|---|---|

| LUVOMAXX® CF 602 | dark grey powder | natural composites of amorphous carbon and cryptocrystalline silica | 85 | 55 | 1.40 | 3.7 |

| LUVOMAXX® CF 603 | dark grey powder | 70 | 56 | 1.55 | 4.3 | |

| LUVOMAXX® CF 704 | dark grey powder | natural composites of amorphous carbon and cryptocrystalline silica | 15 | 29 | 2.50 | 4.5 |

| LUVOMAXX® CF 805 | greyish powder | 8 | 24 | 2.30 | 6.0 |

* laser diffractometry, wet measurement

| Appearance | Specific surface area BET [m2/g] | ash content [%] | Sieve residue > 45μm [%] | pH value | |

|---|---|---|---|---|---|

| LUVOMAXX® Silica HM 1160 | white powder | 145 - 175 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 2160 | white granules | 145 - 175 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 1170 | white powder | 160 - 190 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 2170 | white granules | 160 - 190 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 1180 | white powder | 165 - 195 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| LUVOMAXX® Silica HM 2180 | white granules | 165 - 195 | ≤ 6 | ≤ 0.5 | 5 – 8 |

| Appearance | Specific surface area BET [m2/g] | Sieve residue > 45μm [%] | pH value | |

|---|---|---|---|---|

| LUVOMAXX® Silica HM 150 | white powder | 120 - 180 | ≤ 0.05 | 3.6 – 4.5 |

| LUVOMAXX® Silica HM 200 | white powder | 170 - 230 | ≤ 0.05 | 3.6 – 4.5 |

| LUVOMAXX® Silica HM 300 | white powder | 270 - 330 | ≤ 0.05 | 3.6 – 4.5 |

| LUVOMAXX® Silica HM 380 | white powder | 350 - 410 | ≤ 0.05 | 3.6 – 4.5 |

Rubber Moulding

As official distributors for Lord Corporation (Europe) Ltd, we stock and supply the following product groups, Chemlok, Chemosil, Flocksil and Sipiol.

When you need a rubber-to-substrate adhesive, choose the ultimate in elastomer bonding — LORD Chemlok® and Chemosil® Adhesives — technology that has generations of proven performance.

For more than 50 years, Chemlok and Chemosil Adhesives have performed in abroad spectrum of industries including: automotive, power generation, civil engineering, mining, aerospace, military, oil and gas, and industrial applications, to name a few. For uncompromising quality, service and performance.

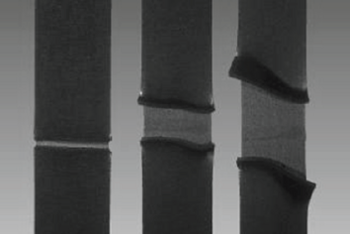

LORD Flocksil® Weatherstrip Adhesives insulate and form a seal around automotive windows. Flocksil allows the adhesion of flock to many rubber and plastic substrates.

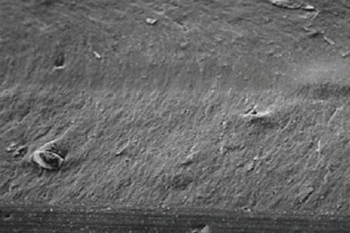

LORD Sipiol® Weatherstrip Coatings help improve the performance of elastomeric seals and substrates used on passenger and commercial vehicles and ensure a quiet and dry ride for passengers.

Our coatings are formulated to withstand a variety of challenging environments including weathering, heat and fluids, and abrasive environments. Additionally weatherstrip coatings are also designed to lower the coefficient of friction between elastomer and glass and painted metal to improve slip and anti-static "squeak and itch" characteristics.

Please find here the following broschures:

LORD Chemosil®/LORD Chemlok® Rubber-to-Substrate Adhesives for the industry

As distributors in the UK for McGee industries we supply there range of McLube products.

These are environmentally safe, effective, and economical Mould Release Agents, Mould Release Sprays, and Antistick Coatings to meet virtually every manufacturing need.

McLube’s Mould Release Agents and Coatings include the latest technology and are based on polytetrafluoroethylene (PTFE), fluorochemical and resin based formulations.

McLube Mould Release Agents and Mould Release Sprays are designed specifically for use with all types of rubber, plastic, composites, wood fibre composites/panel pressing, concrete, stone veneers and polyurethane parts. Suitable for use on a wide variety of moulding and other processes, including laminating, extruding, filament winding and hose manufacturing.

McLube mould release agent technology provides high value-in-use products which are effective through multiple cycles, to keep tools clean longer and productivity levels high. There is no transfer to moulded parts and no interference with finishing and bonding.

LUVOMAXX Video

Please accept the External Content Cookie option if you want to play this video. Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Your personal contact