Experts in rheology, polymers and additives.

Our Performance Additives business unit aspires to be a reliable and expert partner for producers of adhesives and sealants, paints and varnishes, printing inks, and construction chemical products.

Combining comprehensive raw material expertise for the specified fields of application and advanced laboratories, we are able to continually develop new products and applications, whilst still ensuring excellent technical support to our partners. As both an independent distributor and an experienced producer, we are able to work closely with customers to obtain significant benefits.

Binders

DIANAL Acrylic Resins – Specialty Resins for Coatings, Inks, and Adhesives

Mitsubishi Chemical specialty resins are polymers or copolymers of methyl methacrylate or other monomers, for use in specialty coatings, inks, and adhesives formulations. The broad portfolio of resins offer the combination of properties associated with high-quality coating resins, such as outstanding resistance to ultraviolet degradation, excellent weather-ability, superior abrasion resistance, excellent resistance to water, alcohol, dilute acids and alkalis, chemical fumes and corrosive and oxidizing environments, high gloss and hardness, generally low pigment reactivity, water-white color and transparency, as well as, resistance to discoloration from heating.

Mitsubishi Chemical produces bead resins by aqueous suspension polymerization. The benefits of this process are narrow polydispersity, excellent resin formulation capabilities, solvent-free as well as free flowing products that dissolve rapidly in a variety of organic solvents.

Product overview

Typical Properties1 of DIANAL Acrylic Resins

| Product | Tg [°C] | Mw | Application |

|---|---|---|---|

| DIANAL BR-53 | ~56 | 65,000 | DIANAL BR-53 is a solid styrene acrylic resin designed for use in wet concrete coatings. DIANAL BR-53 shows good water release performance, excellent humidity and water resistance, flexibility, and pigment dispersibility. |

| DIANAL BR-57 | ~56 | 55,000 | DIANAL BR-57 is a solid styrene acrylic resin designed for higher solids coatings and the concrete marketplace with similar properties to DIANAL BR-53 being the lower molecular weight alternate. |

| DIANAL BR-73 | ~97 | 80,000 | DIANAL BR-73 is a solid acrylic resin to formulate very hard coatings with improved solubility, flexibility, adhesion, and pigment dispersibility. It is particularly designed for masonry applications to improve moisture resistance. |

| DIANAL BR-80 | ~104 | 105,000 | DIANAL BR-80 is a solid acrylic resin to formulate very hard coatings with outstanding durability and weather resistance. It is particularly designed for vinyl top coatings in automotive and upholstery applications to achieve excellent hardness, toughness, and plasticizer barrier, and as non-reactive blending resin for UV coatings in order to modify viscosity, control film shrinkage, improve adhesion and flexibility, as well as, reduce costs. |

| DIANAL BR-87 | ~105 | 30,000 | DIANAL BR-87 is a hard, higher acid solid acrylic resin particularly designed for excellent pigment dispersibility. It can be used to improve hardness and adhesion for metal coatings, to act as solvent barrier for plastic coatings, to enhance adhesion, hardness, and flexibility in graphic arts applications, and to develop excellent adhesion and mechanical properties in adhesives for construction bolt cements. |

| DIANAL BR-101 | ~48 | 145,000 | DIANAL BR-101 is a relatively hard, thermoplastic acrylic resin with excellent solubility in aliphatic solvents and alcohols (also weak solvents). DIANAL BR-101 is used for screen printing inks, art work such as decals, aerosol lacquers, and as temporary binder due to its very clean “burn out” properties. |

| DIANAL BR-106 | ~47 | 60,000 | DIANAL BR-106 is a general-purpose resin with very fast solvent release and broad solubility in aromatics, ketones, acetates, and carbonates. DIANAL BR-106 is used for metal, marine and container coatings, rood marking paints, toners, and plastic coatings. |

| DIANAL BR-107 | ~49 | 75,000 | DIANAL BR-107 is a moderately hard and flexible solid acrylic resin with broad solvent solubility designed for use in heat seal adhesives and coatings. |

| DIANAL BR-113 | ~75 | 30,000 | DIANAL BR-113 is a general-purpose solid acrylic resin and the harder version of DIANAL BR-106. It is particularly suited to improve hardness and adhesion for metal coatings and rotogravure inks, as well as, can be used to formulate aerosol lacquers due to excellent spray-ability. |

| DIANAL BR-115 | ~46 | 55,000 | DIANAL BR-115 is a solid acrylic resin particularly designed for compatibility with medium and long oil alkyd resins. When DIANAL BR-115 is used to modify these alkyd resins, coatings with faster drying speed and better retention of color and gloss result. |

| DIANAL BR-116 | ~48 | 50,000 | DIANAL BR-116 is a solid acrylic resin with particularly advanced pigment dispersibility and broad applicability as stand-alone resin for conventional coatings and self-leveling floorings and as non-reactive blending resin for UV coatings. |

| DIANAL BR-117 | ~35 | 140,000 | DIANAL BR-117 is a solid acrylic resin designed for use in heat seal adhesives and coatings. DIANAL BR-117 is a modified version of DIANAL BR-107 with increased adhesion and toughness. |

| DIANAL BR-220 | ~50 | 65,000 | DIANAL BR-220 is a solid acrylic resin that offers excellent alcohol solubility and a good combination of properties for use in flexographic inks and as clear coating over bright metals such as silver, copper, and brass. |

| DIANAL MB-2543 | ~47 | 35,000 | DIANAL MB-2543 is a general-purpose solid acrylic resin to formulate high solids, low VOC performance coatings. |

| DIANAL MB-2588 | ~33 | 120,000 | DIANAL MB-2588 is a solid acrylic resin that is very well soluble in weak solvents to formulate softer, more flexible systems such as adhesives for staple cement or heat seal lacquers. |

| DIANAL MB-2594 | ~88 | 8,000 | DIANAL MB-2594 is an ultra-low molecular weight solid acrylic resin with acid functionality to achieve outstanding pigment dispersibility. |

| DIANAL MB-2595 | ~85 | 11,000 | DIANAL MB-2595 is an ultra-low molecular weight solid acrylic resin with amine functionality to achieve outstanding pigment dispersibility. |

| DIANAL MB-2752 | ~50 | 25,000 | DIANAL MB-2752 is an acrylic bead resin with highest OH-functionality for 2-pack coatings cured with melamine type or isocyanate type cross-linkers. |

| DIANAL MB-2823 | ~80 | 25,000 | DIANAL MB-2823 is a solid acrylic resin with excellent compatibility with short oil alkyd resins. |

| DIANAL MB-2876 | ~75 | 25,000 | DIANAL MB-2876 is an acrylic bead resin with OH-functional groups. DIANAL MB-2876 can be cured with melamine type or isocyanate type cross-linkers and provides very high toughness. |

| DIANAL MB-2935 | ~84 | 25,000 | DIANAL MB-2935 is an acrylic bead resin with OH-functional groups. DIANAL MB-2935 can be cured with melamine type or isocyanate type cross-linkers. |

| DIANAL MB-3070 | ~52 | 100,000 | DIANAL MB-3070 is a solid, high molecular weight acrylic resin that provides very good mechanical properties. |

| DIANAL MB-7017 | ~47 | 45,000 | DIANAL MB-7017 is a general-purpose solid acrylic resin with broad compatibility in typically used resins and organic solvents to formulate coatings. |

| DIANAL MB-7022 | ~46 | 25,000 | DIANAL MB-7022 is a solid, low molecular weight acrylic resin particularly suited to improve adhesion to reactive cure systems. |

| DIANAL PB-204 | ~94 | 12,000 | DIANAL PB-204 is a solid, low molecular weight acrylic resin with high acidity that achieves excellent adhesion and can be broadly applied to water-reducible coatings upon full neutralization with an amine of choice. |

| DIANAL PB-588 | ~41 | 100,000 | DIANAL PB-588 is a solid, high molecular weight acrylic resin with high acidity that achieves excellent adhesion and can be broadly applied to water-reducible coatings upon full neutralization with an amine of choice. |

| DIANAL TB-044 | ~48 | 60,000 | DIANAL TB-044 is a solid acrylic resin that provides a very low solution viscosity in a broad range of organic solvents and is particularly suited to formulate low VOC coatings. |

| DIANAL TB-250 | ~129 | 7,000 | DIANAL TB-250 is a solid acrylic resin with high compatibility to various resins, excellent pigment wetting properties, and Swiss ordinance and Nestle compliance. |

| DIANAL TB-316 | ~54 | 9,000 | DIANAL TB-316 is a solid acrylic resin with high OH-functionality that is particularly suited for use in automotive refinish and other specialty coatings. |

| DIANAL TB-322 | ~48 | 60,000 | DIANAL TB-322 is a solid acrylic resin that provides excellent adhesion to various metallic substrates such as steel, aluminum, brass, bronze, and copper. |

1 Typical values, not for specification purposes

Typical Properties1 of DIANAL LP Acrylic Resin Powder Series

| Product | Tg [°C] | Mw | Application |

|---|---|---|---|

| DIANAL LP-3104 | ~71 | 700,000 | DIANAL LP-3104 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-3104 is typically used for underbody coats, body and mastic sealer, and other plastisol applications as well as viscosity modifier for thermoset resins. |

| DIANAL LP-3106 | ~72 | 700,000 | DIANAL LP-3106 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-3106 is typically used for underbody coats, body and mastic sealer, and other plastisol applications, floorings, as well as viscosity modifier for thermoset resins. |

| DIANAL LP-3109 | ~83 | 700,000 | DIANAL LP-3109 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-3109 is typically used for mastic sealer and other plastisol applications, floorings, as well as viscosity modifier for thermoset resins. |

| DIANAL LP-3121 | ~102 | 700,000 | DIANAL LP-3121 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-3121 is typically used for underbody coats, body sealer, and other plastisol applications as well as viscosity modifier for thermoset resins. |

| DIANAL LP-3130 | ~100 | 700,000 | DIANAL LP-3130 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-3130 is typically used for underbody coats, body sealer, and other plastisol applications as well as viscosity modifier for thermoset resins. |

| DIANAL LP-3202 | ~77 | 900,000 | DIANAL LP-3202 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-3202 is typically used for mastic sealer and other plastisol applications, textile printing inks, as well as viscosity modifier for thermoset resins. |

| DIANAL LP-3207 | ~77 | 900,000 | DIANAL LP-3207 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-3207 is typically used for mastic sealer and other plastisol applications, textile printing inks, as well as viscosity modifier for thermoset resins. |

| DIANAL LP-4100 | ~27 | DIANAL LP-4100 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-4100 is typically used as impact modifier for epoxy and MMA reactive adhesives, powder coatings, as well as liquid coatings and inks. | |

| DIANAL LP-4200 | ~27 | DIANAL LP-4200 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-4200 is typically used as impact modifier for epoxy and MMA reactive adhesives, powder coatings, as well as liquid coatings and inks. | |

| DIANAL LP-5013 | ~75 | 44,000 | DIANAL LP-5013 is a powdery, finer particle size acrylic copolymer resin with very fast solubility in organic solvents. DIANAL LP-5013 is typically used as binder for coatings and inks as well as polyurethane hot melt adhesives. |

1 Typical values, not for specification purposes

Functional Fillers

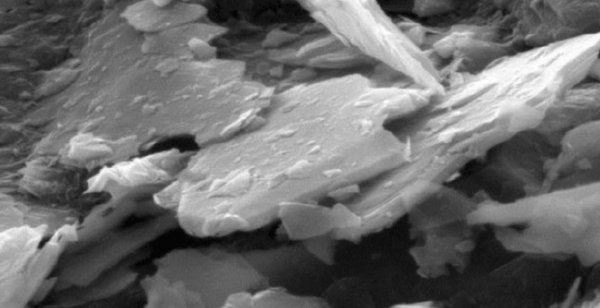

MAGRIS TALC series - lamellar and microcrystalline talcs for Paints & Coatings applications

Mineral fillers for paint and coatings improve or influence technical and / or optical properties such as colour, hiding power and brightness. They are used to increase the volume, change the material density value and reduce the formulation costs of end customers. Other properties can be the anticorrosion protection in lacquers, influence of rheology in paints, increase scratch resistance and improve UV protection or flame-resistance of end products.

| Rheology Performance | Physical Properties |

|---|---|

|

|

ARTIC MIST®, CIMPACT®, JetWhite®, JetFill®, JetFill®M, MAGRIS TALC MISTRON®, NICRON®, SIERRALITE®, SILVERLINE®, STELLAR®, VERTAL®, YELLOWSTONE®

In the modern world of paint industry today, talc is more than a simple mineral filler. MAGRIS TALC offers highly lamellar talc products as well as microcrystalline and engineered types fine-grades reduced.

Bright white JETWHITE® und MISTRON® products as well as cost-effective NICRON® and SILVERLINE® products offer the laboratory developer a high degree of flexibility to balance the advantages of technical colour performance and improved process ability with rising raw material prices and higher production output.

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| JetWhite® 1H/HC | Natural white powder, submicron talc, bags | Additive for decorative paints, can coating | For maximum hiding power and brightness, TiO2 extender | 1.1 | ca. 6 (Hegman 7.5) | Y90 |

| JetWhite® 7H/HC | Natural white powder, ultrafine talc, bags | Additive for decorative paints, can coating | For maximum hiding power and brightness, TiO2 extender | 1.9 | ca. 8 (Hegman 7) | Y91 |

| NICRON® 665 | Natural white powder, microcrystalline talc, bags | Architectural and industrial primers and topcoats | Film strength and flexibility, provides barrier properties, very bright | 1.2 | ca. 9 (Hegman 6.5) | 87 |

| MISTRON® MONOMIX | Natural white powder, micronzed talc, bags | Engineered and high performance, industrial and primers, protective coatings | High surface area and tight top-size control, anticorrosive functionality, rheology contribution | 2 | ca. 10 (Hegman 6) | 88 |

| NICRON® 604 SILVERLINE® 604 | Natural white powder, microcrystalline talc, bags | Architectural and industrial primers and topcoats | Film strength and flexibility, provides barrier properties, improve corrosion resistance and stain-blocking ability | 2.3 | ca. 12 (Hegman 6) | 85 |

| STELLAR® 510 | Natural white powder, lamellar talc, bags | Architectural and topcoats where high brightness is needed | Film strength and flexibility, provides barrier properties, very bright | 5 | ca. 15 (Hegman 5.5) | Y88 |

| SILVERLINE® 504 | Natural white powder, microcrystalline talc, bags | Architectural and industrial primers, non-color sensitive applications | Improve corrosion resistance and stain-blocking ability, improve sag resistance and maximize prime pigment extension | 3.2 | ca. 20 (Hegman 5) | 81 |

| NICRON® 403 MISTRON® 403 | Natural white powder, microcrystalline talc, bags | Architectural, wood and industrial primers and topcoats | Film strength and flexibility, provides barrier properties, semi-transparent wood stains to prevent tannin bleed, improve corrosion resistance and stain-blocking ability | 4.7 4.5 | ca. 25 (Hegman 4) | 83 86 |

| JetWhite® 4H | Natural white powder, medium talc, bags | Decorative paints, architectural and industrial primers | Improve barrier properties which impart corrosion resistance and stain blocking ability | 5.7 | (Hegman 4-4.5) | Y90 |

| VERTAL® 77 | Natural white powder, talc/carbonate mineral pigment, bags | Waterborne primers architectural and industrial, stain-blocking primers, sealers, undercoaters | Provides a unique balance of prime pigment spacing (opacity), film reinforcement, anti-cracking and barrier properties | 9 | ca. 25 | 78 |

| NICRON® 303 | Natural white powder, microcrystalline talc, bags | Architectural, wood and industrial primers, also adhesive, sealant, caulk, joint compound, wood putty, and auto body patch applications | Film strength and flexibility, provides barrier properties, improve corrosion resistance and stain-blocking ability, good sandability | 7 | ca. 30 (Hegman 3) | 82 |

| MISTRON® 303 NICRON® 302 | Natural white powder, microcrystalline engineered talc, bags | Protective coatings and marine coating applications, architectural flat exterior latex paints | Disperses easily in high-solids and solvent-borne coatings, good paint stability, rheology and anti-settling properties. Low sheen, good touch-up, good fade- and chalk-resistance | 7.5 13 | ca. 35 (Hegman 3) | 80 84 |

| VERTAL® 92 | Natural white powder, talc/carbonate mineral pigment, bags | Auto Rep Grouts, Car Putties Autofill | Highly lamellar talc, macrocrystalline 200 Mesh, good sanding for abrasive paper use | 17.5 | ca. 45-50 | Y72 |

| SILVERLINE® 202 | Natural white powder, microcrystalline engineered talc, bags | Airless-spray architectural waterborne flat paints | Engineered talc recommended where low viscosity build pigments are required, providing excellent sheen control, scrub resistance with minimal wear on airless spray equipment | 19.8 | ca. 50 (Hegman 2.5) | 76 |

| JetWhite® 2H | Natural white powder, coarser talc, bags | Decorative paints, architectural and industrial primers | Improve barrier properties which impart corrosion resistance and stain blocking ability | 11 | ca. 60 (Hegman 2) | Y87 |

| JetFil® M200 | Natural white powder, bags | General purpose applications for coarse talcs | High purity, platy, coarse talc | 10 | ca. 60 (Hegman 2) | Y78 |

| SILVERLINE® 001 | Natural white powder, bags | Industrial floor screed, coarse filler | Concrete form lubricant, parting agent for rolled asphalt, roofing, floor tile | 14 | ca. 40 - 60 | off white |

| VERTAL® AF | Natural white powder, UL Environment labeled for sustainability, only BB 2000 lbs | Construction, Bitumen Roofing, Flooring, Adhesives, Sound Damping | Talc with high magnesite content | 23 | 325 Mesh (44 µm) %passing 60-85 | off white |

MAGRIS TALC series - natural talcs for putties and liquid compounds, adhesives and sealings

MAGRIS Talc products are high-purity, functional additives ideal for putties and liquid compounds. Talc improves dimensional stabilityand reinforces putties and liquid compounds, giving added protection, against cracking and shrinking. Talc is the industry standard for sanding properties and polishing properties.

For putties and liquid compounds, adhesives and sealants we can offer also products from VERTAL® series with carbonic binding.

| Applications | Physical Properties |

|---|---|

|

|

| Product | Form | Application | Benefits | D50 sedigraph | D98 sedigraph | Brightness [GEB] |

|---|---|---|---|---|---|---|

| NICRON® 302 | Natural white powder, bags | Sealants and Caulks, Pressure Sensitive and Structural Adhesives | High loading low viscosity, high brightness | 13 | ca. 30 (Hegman 3) | Y82 |

| SILVERLINE® 303 | Natural white powder, bags | Pastes & Mastics, cementitious and self-leveling Compounds, fine | Finer top-size for smooth Finishes and application properties | 6,1 | ca. 40 | 78 |

| VERTAL® 92 | Natural white powder, talc/carbonate mineral pigment, bags | Auto Rep Grouts, Car Putties Autofill | Highly lamellar talc, macrocrystalline 200 Mesh, good sanding for abrasive paper use | 17,5 | ca. 45 | Y72 |

| VERTAL® 97 | Natural white powder, talc/carbonate mineral pigment, bags | Pastes & Mastics, cementitious and self-leveling Compounds | Highly lamellar talc, macrocrystalline 200 Mesh, good sanding for abrasive paper use | 15 | 50 | Y72 |

| SILVERLINE® 002 | Natural white powder, bags | Pastes & Mastics, cementitious and self-leveling Compounds | High loading low viscosity | 8,4 | 55 | 75 |

| VERTAL® TC-100 | Natural white powder, talc/carbonate mineral pigment, bags | Pastes & Mastics, cementitious and self-leveling Compounds | Improves resistance to cracking, smoothing and sandability, macrocrystalline 200 Mesh | 16,4 | 325 Mesh (44 µm) %passing 88 | off white |

| VERTAL® AF | Natural white powder, UL Environment labeled for sustainability, only BB 2000 lbs | Construction, Bitumen Roofing, Flooring, Adhesives, Sound Damping | Talc with high carbonate (Mg) content, improved dimensional stability, cross-flow mechanical performance, and flexural stiffness | 23 | 325 Mesh (44 µm) %passing 60-85 | off white |

Talc is oleophilic which gives it the ability to associate with liquid resins such as alkyds, epoxies, polyesters, acrylics, amines and polyols. In doing so, they create weak bonds with these resins that result in increased low-shear viscosity. When shear is applied the bonds break quickly, resulting in shear-thinning rheology that is ideal for many applications.

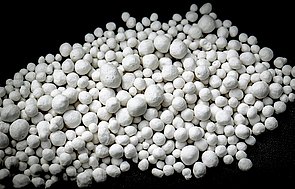

Cenospheres OMEGA-SPHERES®

Hollow ceramic microspheres are extremely resistant hollow spheres, which are formed under the exposure of extreme heat. Temperatures over the relevant melting points are required to achieve a ceramic melting. Drops with a hollow are formed as a result of the subsequent rapid cooling process. The OMEGA-SPHERES® formed in this way are refined and fractionated in subsequent processes, thus being a high-quality raw material in your formulations.

The spheres we provide are produced at various production sites for global availability. Globally produced standard types are manufactured in Turkey, Central Asia and Germany. Special types are produced in Germany. There are further suppliers in Europe and throughout the world.

OMEGA-SPHERES®, White

Description

OMEGA-SPHERES® W are marked by a particularly high thermal resistance, low iron content and a white colour. They are available in different distribution particle sizes.

Application

Because of their particularly high heat resistance, OMEGA-SPHERES® W are preferentially used in the refractory and foundry industries. The white colour allows their use in aesthetically demanding applications such as decorative plasters and wall paints.

| Products | Particle size [μm] | Bulk density [kg/m³] | Crush strength [MPa] | Temperature max. [°C] |

|---|---|---|---|---|

| OMEGA-SPHERES® W150 | 0 - 150 | 410 | 25 | 1,600 |

| OMEGA-SPHERES® W300 | 0 - 300 | 410 | 25 | 1,600 |

| OMEGA-SPHERES® WM | 150 - 300 | 390 | 25 | 1,600 |

| OMEGA-SPHERES® W250-6 | 250 - 700 | 400 | 25 | 1,600 |

The stated values correspond to typical values and hence do not represent a specification.

Cenospheres THERMO-SPHERES®

THERMO-SPHERES®, White

Description

THERMO-SPHERES® W are white, high quality hollow ceramic microspheres < 150 μm, which are characterised by a high degree of fineness as well as a particularly high mechanical strength. The products are pre-dried and usable for foundry industry. The white colour allows their use in aesthetically demanding applications such as decorative plasters and wall paints.

Application

THERMO-SPHERES® W are used in bright applications which require the use of the smallest possible microspheres or make high demands on surface quality. This includes applications in addition to the use in paints and coatings, surfaces as well as special casting compounds and adhesives where a high whiteness is advantageous.

| Products | Particle size [μm] | Bulk density [kg/m³] | Crush strength [MPa] | Temperature max. [°C] |

|---|---|---|---|---|

| THERMO-SPHERES® W100 | 0 - 100 | 400 | 25 | 1,600 |

| THERMO-SPHERES® W125 | 0 - 125 | 400 | 25 | 1,600 |

The stated values correspond to typical values and hence do not represent a specification.

MATSUMOTO MICROSPHERES® MBF, expanded

Description

Thermally expanded hollow microspheres as 50 % masterbatches.

Application

Blowing agent for extrusion and injection molding; as granules, very good handling and metering properties.

| Products | Pellet size [μm] | Pellet density [g/cm³] | Temperature min. [°C] | Temperature max. [°C] |

|---|---|---|---|---|

| MBF-190EVA50 | 3-5 x 2-5 | ~ 0.9 | 130 – 140 | 185 – 195 |

| MBFN-190SSPE | 3-5 x 2-5 | ~ 0.9 | 160 – 170 | 210 – 220 |

| MBFN-170EVA | 3-5 x 2-5 | ~ 0.9 | 185 – 195 | 170 – 190 |

| MBF-230PE | 3-5 x 2-5 | ~ 0.9 | 180 – 190 | 220 – 230 |

| MBF-260EVA | 3-5 x 2-5 | ~ 0.9 | 190 – 200 | 250 – 260 |

MATSUMOTO MICROSPHERES®, moistened expanded grades

Description

MATSUMOTO MICROSPHERES® of the F-E series are moistened, polymer-based hollow microspheres that make handling much easier and safer. The solids content is about 10 %. The specific weight is in the range of 0.02 to 0.04 g/cm³, which allows a significant reduction of the final product weight.

Application

Lightweight fillers for a wide range of applications where a reduction in density, improvement in insulation as well as mechanical properties and rheological properties are desired. The expanded hollow microspheres show good temperature and solvent resistance and exhibit broad compatibility with a wide variety of a wide range of systems. Pre-expanded microsphere grades do not require elevated process temperatures.

| Products | Average Particle Size [μm] | Polymer | Effective Density [g/cm³] | Solids content [%] | Solvent resistance |

|---|---|---|---|---|---|

| F-30E | 30 – 60 | VC/AN-Copolymer | 0.020 – 0.030 | 9 – 13 | • |

| F-50E | 40 – 60 | Acrylnitril-Copolymer | 0.020 – 0.040 | 11 – 16 | •• |

| F-65E | 40 – 60 | Acrylnitril-Copolymer | 0.020 – 0.030 | 9 – 13 | •• |

Solvent resistance: low: • medium: •• well suited: •••

MATSUMOTO MICROSPHERES®, dry expanded grades

Description

MATSUMOTO MICROSPHERES® hollow microspheres of the F-DE series are pre-expanded, dry polymerbased hollow microspheres. The solids content is at least 97 %. The specific gravity is in the range of 0.010 to 0.035 g/cm³, as a result of which very light end products can be realized.

Application

MATSUMOTO MICROSPHERES® of F-DE are used in applications where a subsequent expansion of the hollow microspheres is not possible or undesirable.

| Products | Average Particle Size [μm] | Polymer | Effective Density [g/cm³] | Solids content [%] | Solvent resistance |

|---|---|---|---|---|---|

| FN-80SDE | 20 – 40 | Acrylnitril-Copolymer | 0.020 – 0.030 | ≥ 97 | •• |

| F-65DE | 40 – 60 | Acrylnitril-Copolymer | 0.025 – 0.035 | ≥ 97 | •• |

| F-80DE | 90 – 130 | Acrylnitril-Copolymer | 0.015 – 0.025 | ≥ 97 | ••• |

| FN-78DE | 100 – 200 | Acrylnitril-Copolymer | 0.010 – 0.020 | ≥ 97 | ••• |

Solvent resistance: low: • medium: •• well suited: •••

MATSUMOTO MICROSPHERES®, expanded hybrid

Description

MATSUMOTO MICROSPHERES® of the MFL series are hybrid hollow microspheres, which are used as a novel functional filler developed. They are polymer-based spheres that are coated with an inorganic powder.

Application

MATSUMOTO MICROSPHERES® MFL have a high elasticity and resistance, so that they can be used even when incorporated under high pressure. The surface coated with inorganic powder enables strength-increasing anchoring of the hollow spheres in the matrix used in each case.

| Products | Average Partice size [μm] | Coating | Effective Density [g/cm³] | Temperature resistance [°C] | Characteristic |

|---|---|---|---|---|---|

| MFL-81GTA | 10 – 30 | Talc | 0.20 - 0.26 | 130 – 140 | Very fine surface |

| MFL-81CGA | 10 – 30 | Calcium carbonate | 0.20 - 0.26 | 130 – 140 | Very fine surface |

| MFL-SEVEN | 20 – 40 | Calcium carbonate | 0.11 - 0.17 | 130 – 140 | Very fine surface |

| MFL-HD30CA | 20 – 40 | Calcium carbonate | 0.11 - 0.17 | 140 – 150 | High pressure |

| MFL-HD60CA | 50 – 70 | Calcium carbonate | 0.10 - 0.14 | 140 – 150 | High pressure |

| MFL-100MCA | 60 – 70 | Calcium carbonate | 0.10 - 0.14 | 150 – 160 | High pressure |

| MFL-110CAL | 90 – 120 | Calcium carbonate | 0.06 - 0.10 | 160 – 170 | Ultra light |

| MFL-UPR60 | 50 - 75 | Calcium carbonate | 0.10 - 0.14 | 140 – 150 | High pressure |

The values given are typical values and therefore do not represent a specification.

MATSUMOTO MICROSPHERES® expandable

Description

MATSUMOTO MICROSPHERES® expandable are polymer-based thermo-expandable microspheres with an average particle size of 5 to 50 μm, which are formed by encapsulating liquid hydrocarbon with a low boiling point in a shell of thermoplastic polymer. Various types are available, suitable for a wide temperature range, from low temperatures starting at about 80°C up to extremely high temperatures of about 260°C.

Application

Lightweight fillers for a wide range of applications in which a reduction in density, improvement in insulation as well as changes in mechanical properties and rheological properties are desired. The expandable hollow microspheres exhibit good temperature and solvent resistance, and exhibit comprehensive compatibility with a wide range of systems. The vast majority of MATSUMOTO MICROSPHERES® are available both dry (D-type) and wetted (unmarked) to best suit the application requirements.

| Products | Particle Size [μm] | Temperature min. [°C] | Temperature max. [°C] | Solvent resistance |

|---|---|---|---|---|

| Products expanding at low temperatures | ||||

| F-35 / F-35D | 10 – 20 | 70 – 80 | 100 – 110 | • |

| HF-36 / HF-36D | 10 – 16 | 70 – 80 | 110 – 120 | • |

| HF-48 / HF-48D | 9 – 15 | 90 – 100 | 125 – 135 | •• |

| FN-80GS / FN-80GSD | 6 – 10 | 100 – 110 | 125 – 135 | •• |

| Products expanding at medium temperatures | ||||

| FN-100SS / FN-100SSD | 6 – 10 | 120 – 130 | 145 – 155 | ••••• |

| FN-100S / FN-100SD | 10 – 20 | 125 – 135 | 150 – 160 | ••••• |

| FN-77 / FN-77D | 25 – 35 | 100 – 110 | 155 – 165 | ••• |

| FN-83GSD | 7 – 14 | 110 – 120 | 150 – 160 | ••• |

| FN-82 / FN-82D | 25 – 35 | 120 – 130 | 160 – 170 | ••• |

| FN-78 / FN-78D | 35 – 50 | 100 – 115 | 150 – 165 | ••• |

| Products expanding at higher temperatures | ||||

| FN-100M / FN-100MD | 20 – 30 | 125 – 135 | 165 – 180 | ••••• |

| FN-105 / FN-105D | 35 – 45 | 120 – 135 | 175 – 185 | ••• |

| FN-185L / FN-185LD | 35 – 50 | 140 – 150 | 180 – 190 | ••• |

| Products expanding at very high temperatures | ||||

| FN-190SSD | 10 – 15 | 155 – 165 | 210 – 220 | ••• |

| F-190D | 30 – 40 | 160 – 170 | 210 – 220 | ••• |

| F-230D | 25 – 35 | 180 – 190 | 220 – 240 | ••• |

| F-260D | 20 – 35 | 190 – 200 | 250 – 260 | ••• |

The values given are typical values and therefore do not represent a specification.

Solvent resistance: low: • medium: •• well suited: ••• recommended: •••••

OMEGA-SIL®

Description

OMEGA-SIL® are solid aluminium silicate spheres which have a very high compressive strength. The OMEGA-SIL® SPECIAL* product range consists of aluminium silicates that are processed in an additional processing step sifted. This particularly sharp separation of the top cut results in aesthetic applications to smoother surfaces.

Application

Due to the lower specific surface the use of OMEGA-SIL® in paints and coatings allows a higher degree of filling. OMEGA- SIL® shows in cementitious systems pozzolanic reactivity. The inside microcrystalline structure results in a significant increase of mechanical strength.

| Products | D50 [μm] | D95 [μm] | Effective density [g/cm³] | Bulk density [kg/m³] |

|---|---|---|---|---|

| OMEGA-SIL® XS | 3.5 | 9.5 | 2.51 | 780 |

| OMEGA-SIL® S | 4.5 | 11.5 | 2.48 | 800 |

| OMEGA-SIL® M | 6.5 | 30.0 | 2.40 | 870 |

| OMEGA-SIL® L | 12.5 | 75.0 | 2.39 | 880 |

| OMEGA-SIL® XL | 50.0 | 200.0 | 2.25 | 1,090 |

| OMEGA-SIL® XS SPECIAL | 3.5 | 9.5* | 2.51 | 780 |

| OMEGA-SIL® S SPECIAL | 4.5 | 11.5* | 2.48 | 800 |

| OMEGA-SIL® M SPECIAL | 6.5 | 30.0* | 2.40 | 870 |

Product items shown with an asterisk * describe top cut (d98) modified versions for aesthetical surfaces.

The stated values correspond to typical values and hence do not represent a specification.

LITHO-BUBBLES®

Description

LITHO-BUBBLES® are silicate based mineral granules. They are multicellular, open celled foam granulate which has many different uses as lightweight filler.

Application

LITHO-BUBBLES® are used as lightweight filler in aqueous, solvent-containing and solvent-free systems such as paints and coatings, refractory and foundry products, mould making, grinding agents or construction chemical products.

| Products | Particle size distribution [μm] | Bulk density [kg/m³] |

|---|---|---|

| LITHO-BUBBLES® 40 | 0 - 40 | 650 |

| LITHO-BUBBLES® 100 | 40 - 100 | 470 |

| LITHO-BUBBLES® 300 | 100 - 300 | 340 |

| LITHO-BUBBLES® 600 | 300 - 600 | 390 |

The stated values correspond to typical values and hence do not represent a specification.

LITHO-BUBBLES®, hydrophobic

Description

LITHO-BUBBLES® H is a hydrophobic mineral granule, multi-cellular, open-celled foam granulate which has many different uses as lightweight filler.

Application

LITHO-BUBBLES® are preferentially used as lightweight filler in aqueous but also in solvent-containing and solvent-free systems such as paints and coatings, refractory and foundry products, mould making, grinding agents or construction chemical products. Sometimes customer wish a hydrophobic treatment for special use in cement base systems for building and construction.

| Products | Particle size distribution [μm] | Bulk density [kg/m³] |

|---|---|---|

| LITHO-BUBBLES® 100H | 40 - 100 | 470 |

| LITHO-BUBBLES® 300H | 100 - 300 | 340 |

| LITHO-BUBBLES® 600H | 300 - 600 | 390 |

| LITHO-BUBBLES® 1000H | 500 - 1000 | 330 |

The stated values correspond to typical values and hence do not represent a specification.

OMEGA-BUBBLES® C - ultra white

OMEGA-BUBBLES® C are multicellular expanded glass granules. The high whiteness can help to reduce the addition of titanium dioxide in cementitious formulation. For aesthetic applications like acoustic construction or ceilings the ultra-white lightweight fillers meet today's spirit of time. OMEGA-BUBBLES® C being based on selected recycled glass. Using these products is sustainable and environmentally friendly and can reduces your green CO2 footprint in later disposal issues.

OMEGA-BUBBLES® C are available in the grain sizes customary on the market for the construction and insulation industry.

| Products | Particle size range [mm] | Grain gross density [kg/m³] | Bulk density [kg/m³] |

|---|---|---|---|

| OMEGA-BUBBLES® C-XS | 0.1 - 0.3 | 680 - 920 | 340 - 460 |

| OMEGA-BUBBLES® C-S | 0.25 - 0.5 | 460 - 620 | 255 - 345 |

| OMEGA-BUBBLES® C-M | 0.5 - 1.0 | 380 - 510 | 210 - 290 |

| OMEGA-BUBBLES® C-L | 1.0 - 2.0 | 310 - 420 | 190 - 250 |

| OMEGA-BUBBLES® C-XL | 2.0 - 4.0 | 260 - 360 | 160 - 220 |

The stated values correspond to typical values and hence do not represent a specification.

LUVOFIL® TEC – Unique Class of Multi-purpose Functional Fillers

LUVOFIL® TEC comprises a portfolio of multi-purpose functional fillers based on the world’s first polymer foam with pores in the nanometer range. Produced based on a patent-protected process and foamed with a 100% climate-friendly blowing agent, an entirely new class of materials with a pore size reduction of the factor 1000 compared to conventional polymer foams is provided leading to a unique and multi-purpose performance profile.

Product overview:

| Products | Description | Particle Size D50 [µm] | Particle Size D100 [µm] | Application |

|---|---|---|---|---|

| LUVOFIL® TEC 50 | LUVOFIL® TEC 50 is a foamed, highly hydrophobic, thermoplastic polymer delivered as white powder with the lowest tamped density possible. | <15 | <50 | LUVOFIL® TEC 50 is used to achieve deep matting at highest transparency, anti-burnishing, mar, scratch, and scuff resistance, water repellency, water and chemical resistance, as well as water vapor permeability for water-based and solvent-free paints and coatings. Furthermore, LUVOFIL® TEC 50 is applied as matting and rheology control agent (fumed silica replacement) in SMP and silicone-based sealants. Applied as functional filler in cementitious and blow-in insulation systems as well as tile adhesives, LUVOFIL® TEC 50 offers weight reduction, thermal insulation and diffusion-open barrier properties. |

| LUVOFIL® TEC 300 | LUVOFIL® TEC 300 is a foamed, highly hydrophobic, thermoplastic polymer delivered as white powder with the lowest tamped density possible. | <300 | LUVOFIL® TEC 300 is used as functional filler in order to provide weight reduction, thermal insulation and diffusion-open barrier properties in cementitious and blow-in insulation systems as well as tile adhesives. Furthermore, LUVOFIL® TEC 300 is applied as liquid carrier for powder coatings, masterbatches, and compounding with the ability to absorb more than 600 w% liquid depending on its chemical nature, polarity and viscosity. | |

| LUVOFIL® TEC 1000 | LUVOFIL® TEC 1000 is a foamed, highly hydrophobic, thermoplastic polymer delivered as white powder with the lowest tamped density possible. | <1,000 | LUVOFIL® TEC 1000 is used as functional filler in order to provide weight reduction, thermal insulation and diffusion-open barrier properties in cementitious and blow-in insulation systems as well as tile adhesives. Furthermore, LUVOFIL® TEC 1000 is applied as liquid carrier for powder coatings, masterbatches, and compounding with the ability to absorb more than 600 w% liquid depending on its chemical nature, polarity and viscosity. |

Additives

K-WHITE® Anti-corrosive Pigments for Solvent-borne, Water-borne, as well as Powder Coatings

The TAYCA Corporation has been working in the research and development of specialized phosphate materials for many years and has succeeded in the production and commercialization of K-WHITE®. The K-WHITE® range of products are all based on the unique properties and chemistry of Aluminum Triphosphate (AlH2P3O10· 2 H2O) and technology has been pioneered by the TAYCA Corporation throughout the world. A comprehensive range of grades is available to meet the demands of the particular systems into which K-WHITE® products are incorporated.

Product overview:

| Products | Description | Application |

|---|---|---|

| K-WHITE® 82 | K-WHITE® 82 is a standard grade anti-corrosive pigment based on aluminum triphosphate and modified by zinc and silica with particular focus on solvent-borne applications. | K-WHITE® 82 provides excellent anti-corrosive properties for solvent-borne coatings based on long, medium, and short oil alkyds as well as epoxy and polyester resins or chlorinated rubber particularly when applied over steel. This anti-corrosive pigment is also suitable for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® 84 | K-WHITE® 84 is a standard grade anti-corrosive pigment based on aluminum triphosphate and modified by zinc and silica for application in both solvent-borne as well as water-borne coatings. | K-WHITE® 84 provides excellent anti-corrosive properties for solvent-borne coatings based on long, and medium oil alkyds, epoxy and polyester resins as well as water-borne coatings based on water-soluble alkyd resins, epoxy resins and epoxy ester dispersions, as well as vinyl acrylic copolymers particularly when applied over steel. This anti-corrosive pigment is also suitable for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® 84S | K-WHITE® 84S is a standard grade anti-corrosive pigment based on aluminum triphosphate and modified by zinc and silica with particular focus on water-borne applications. | K-WHITE® 84S provides excellent anti-corrosive properties for water-borne coatings based on water-soluble alkyd resins, water-borne epoxy resins, epoxy ester dispersions, acrylic emulsions, and vinyl acrylic copolymers particularly when applied over steel. This anti-corrosive pigment is also suitable for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® 105 | K-WHITE® 105 is a micronized grade anti-corrosive pigment based on aluminum triphosphate and modified by zinc for application in solvent-borne, water-borne, as well as powder coatings. | K-WHITE® 105 provides excellent anti-corrosive properties for solvent-borne coatings based on long, medium, and short oil alkyds, epoxy and polyester resins or chlorinated rubber as well as water-borne coatings based on water-soluble alkyd resins, epoxy resins and epoxy ester dispersions, as well as vinyl acrylic copolymers particularly when applied over steel. This anti-corrosive pigment is also highly recommended for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® 105S | K-WHITE® 105S is a micronized grade anti-corrosive pigment based on aluminum triphosphate and modified by zinc for application in solvent-borne, water-borne, as well as powder coatings. | K-WHITE® 105S provides excellent anti-corrosive properties for solvent-borne coatings based on long, medium, and short oil alkyds, epoxy and polyester resins or chlorinated rubber as well as water-borne coatings based on water-soluble alkyd resins, epoxy resins and epoxy ester dispersions, as well as vinyl acrylic copolymers particularly when applied over steel. This anti-corrosive pigment is also highly recommended for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® G105 | K-WHITE® G105 is a zinc-free, micronized grade anti-corrosive pigment based on aluminum triphosphate and modified by magnesium with particular focus on solvent-borne applications as well as powder coatings. | K-WHITE® G105 provides excellent anti-corrosive properties for solvent-borne coatings based on short oil alkyds, epoxy and polyester as well as powder coatings based on epoxy and polyester resins particularly when applied over zinc galvanized steel, aluminum or magnesium alloys. |

| K-WHITE® 108 | K-WHITE® 108 is a micronized grade anti-corrosive pigment based on aluminum triphosphate and modified by zinc with particular focus on solvent-borne applications as well as powder coatings. | K-WHITE® 108 provides excellent anti-corrosive properties for solvent-borne coatings based on long, medium, and short oil alkyds, epoxy and polyester resins as well as powder coating applications based on epoxy or polyester resins particularly when applied over steel or aluminum. This anti-corrosive pigment is also highly recommended for water-borne coatings based water-borne epoxy resins. |

| K-WHITE® G110 | K-WHITE® G110 is a zinc-free, micronized grade anti-corrosive pigment based on aluminum triphosphate and modified by magnesium with particular focus on solvent-borne applications as well as powder coatings. | K-WHITE® G110 provides excellent anti-corrosive properties for solvent-borne coatings based on short oil alkyds, epoxy and polyester as well as powder coatings based on epoxy and polyester resins particularly when applied over zinc galvanized steel, aluminum or magnesium alloys. |

| K-WHITE® 140W | K-WHITE® 140W is a micronized grade anti-corrosive pigment based on aluminum triphosphate and modified by zinc with particular focus on water-borne applications. | K-WHITE® 140W provides excellent anti-corrosive properties for water-borne coatings based on water-soluble alkyd resins, water-borne epoxy resins, and acrylic emulsions particularly when applied over conventional or zinc galvanized steel. This anti-corrosive pigment is also suitable for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® ZF150W | K-WHITE® ZF150W is a zinc-free anti-corrosive pigment based on aluminum triphosphate and modified by calcium and magnesium for application in solvent-borne, water-borne, as well as powder coatings. | K-WHITE® ZF150W provides excellent anti-corrosive properties for solvent-borne coatings based on long, medium, and short oil alkyds, epoxy and polyester resins or chlorinated rubber as well as water-borne coatings based on water-soluble alkyd resins and acrylic emulsions when applied over steel. This anti-corrosive pigment is also suitable for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® 450H | K-WHITE® 450H is a zinc-free standard grade anti-corrosive pigment based on aluminum triphosphate and modified by magnesium with particular focus on water-borne applications. | K-WHITE® 450H provides excellent anti-corrosive properties for water-borne coatings based on acrylic emulsions and vinyl acrylic copolymers particularly when applied over zinc galvanized steel. This anti-corrosive pigment is also suitable for powder coating applications based on epoxy or polyester resins. |

| K-WHITE® CZ610 | K-WHITE® CZ610 is a standard grade anti-corrosive pigment based on aluminum triphosphate and modified by calcium for application in solvent-borne, water-borne, as well as powder coatings. | K-WHITE® CZ610 provides excellent anti-corrosive properties for solvent-borne coatings based on long, medium, and short oil alkyds, epoxy and polyester resins or chlorinated rubber as well as water-borne coatings based on water-soluble alkyd resins as well as epoxy and acrylic emulsions when applied over cold rolled steel. |

| K-WHITE® Ca650 | K-WHITE® Ca650 is a zinc-free standard grade anti-corrosive pigment based on aluminum triphosphate and modified by calcium with particular focus on solvent-borne applications and powder coatings. | K-WHITE® Ca650 provides excellent anti-corrosive properties in conjunction with epoxy and polyester resins for both solvent-borne as well as powder coatings particularly when applied over zinc galvanized steel. This anti-corrosive pigment is also suitable for water-borne coating applications based on a broad variety of commonly used resin technologies. |

| K-WHITE® TC720 | K-WHITE® TC720 is a zinc-free standard grade anti-corrosive pigment based on a silica and magnesium compound for application in solvent-borne, water-borne, as well as powder coatings. | K-WHITE® TC720 provides excellent anti-corrosive properties in conjunction with epoxy and polyester resins for both solvent-borne and powder coatings particularly as well as water-borne coatings based on epoxy resins, epoxy ester dispersions, and acrylic emulsions when applied over zinc, galvanized steel or magnesium alloys. |

| K-WHITE® G730 | K-WHITE® G730 is a zinc-free standard grade anti-corrosive pigment based on a silica and magnesium compound for application in solvent-borne coatings. | K-WHITE® G730 provides excellent anti-corrosive properties in conjunction with resins typically used for solvent-borne coil coating primer when applied over non-ferrous substrates, particularly zinc galvanized steel. |

| K-WHITE® G750 | K-WHITE® G750 is a zinc-free standard grade anti-corrosive pigment based on a silica and magnesium compound for application in solvent-borne coatings. | K-WHITE® G750 provides excellent anti-corrosive properties in conjunction with resins typically used for solvent-borne coil coating primer when applied over non-ferrous substrates, particularly zinc galvanized steel. |

LUVOMAXX® Silanes – Broad Portfolio of Multi-functional Agents for Coatings, Adhesives, Sealants, as well as, Building and Construction Materials

LUVOMAXX® silanes are functional organosilanes that are broadly applicable as adhesion promotors to a broad range of different polymers and resin technologies in order to improve wet and dry adhesion on multiple (inorganic) substrates, in particularly those, that offer OH-functional surfaces. LUVOMAXX® silanes do not only interact at the interface polymer/substrate but are also used as coupling agents to improve the reinforcement of fillers within polymeric matrices by the formation of covalent linkages between the polymer system and OH-functional fillers.

Additionally, LUVOMAXX® silanes are typically applied as moisture-catalyzed crosslinkers in (reactive) coating, adhesive, and sealant systems, particularly those based on polyurethanes, silicones, and MS polymers in order to improve mechanical and chemical properties such as increased tensile strength, advanced elastic modulus, improved scratch, abrasion, and notch impact resistance, as well as, better resistance to organic solvents, heat, or UV rays. Due to its selective reactivity, LUVOMAXX silanes (particularly amino-functional ones) can be also used to endcap amino-reactive polymers, e.g. isocyanate pre-polymers or epoxy-based polymers.

Furthermore, LUVOMAXX® silanes are used as hydrophobing agents in order to achieve mass hydrophobing and water-proofing, water repellency, as well as, improved moisture and corrosion resistance in building and construction materials or as water-scavenger and drying agent in moisture-sensitive and moisture-cured formulations such as hybrid systems based on silan-terminated polymers.

Product overview:

| Products | Description | Application |

|---|---|---|

| LUVOMAXX® OCTASIL | Triethoxy-n-octylsilane | LUVOMAXX® OCTASIL is used as hydrophobing agent and surface modifier for a variety of inorganic surfaces such as glass, glass fibres, mineral wool, silica, clay, mica, ATH and other hydroxides. Furthermore, LUVOMAXX® OCTASIL is applied as adhesion promoter and coupling agent that can physically interact via its non-polar alkyl chains with corresponding polymers in order to improve the reinforcement of fillers within the polymeric matrices. |

| LUVOMAXX® VINYLOSIL T102 | Triethoxyvinylsilane | Due to its pronounced tendency to hydrolyze rapidly, LUVOMAXX® VINYLOSIL T102 is used as water-scavenging and drying agent in moisture-sensitive and moisture-cured formulations such as hybrid systems based on silan-terminated polymers in order to improve the storage stability and to prevent the systems from undesired curing. |

| LUVOMAXX® VINYLOSIL T103 | Trimethoxyvinylsilane | Due to its pronounced tendency to hydrolyze rapidly, LUVOMAXX® VINYLOSIL T103 is used as water-scavenging and drying agent in moisture-sensitive and moisture-cured formulations such as hybrid systems based on silan-terminated polymers in order to improve the storage stability and to prevent the systems from undesired curing. |

Further products can be made available on request.

Manufacturer: ADM

| Products | Description | Application |

|---|---|---|

| ADM 500 | Amphoteric dispersant, based on regenerative raw materials | For solvent-based and solvent-free systems, highly effective for carbon blacks, organic and inorganic pigments |

| ADM 2100 | Amphoteric dispersant, based on regenerative raw materials | For solvent-based and solvent-free systems, easy to incorporate, highly effective for carbon blacks, organic and inorganic pigments |

| ADM 3100 | Amphoteric, non-polymeric, APE-free dispersant based on regenerative raw materials | For water-based, decorative paints and industrial coatings, especially effective wetting of inorganic pigments, enables formulation of universal pastes |

| ADM 3200 | Amphoteric, non-polymeric, APE-free dispersant based on regenerative raw materials, contains groups with pigment affinity | For water-based, decorative paints and industrial varnishes, especially effective wetting of organic pigments and carbon blacks, enables formulation of universal pastes |

| ADM 6200 | Amphoteric, non-polymeric, APE-free dispersant based on regenerative raw materials, contains groups with pigment affinity | For water-based systems, highly effective for all types of white and coloured pigments, enables formulation of universal pastes |

| ADM 1000 | Non-ionic surfactant, multifunctional | Excellent steric stabilization, low foaming tendency, used in combination with ADM 3100 and 3200 |

| ADM 1500 | Polyether polyol | Product for combination with ADM 3200 and ADM 6200, promotes the adsorption of these dispersants on the pigment surfaces |

LUVOPLUS® DA 100 - From Emulsification to Multiphase Stabilization

Unique Green Formulation Additive for Aqueous and Non-aqueous Applications

Product Overview:

| Products | Description | Application |

|---|---|---|

| LUVOPLUS® DA 100 | LUVOPLUS® DA 100 is a multifunctional emulsifier / compatibilizer / dispersing additive based on a low molecular weight polymer with amphiphilic properties. | LUVOPLUS® DA 100 is characterized in particular by improving the emulsifiability and extending the storage stability of W/O and O/W emulsions. Furthermore, LUVOPLUS® DA 100 is particularly suitable both for dispersing organophilic bentonites (conventional phyllosilicates, e.g. LUVOGEL®) within the production of pre-gels and for dispersing and stabilizing inorganic pigments and particles in conventional/solvent-based coating systems. The (subsequent) use of LUVOPLUS® DA 100 in solvent-based or water-based base paints also improves the colorant acceptance and the compatibilization of pigment concentrates. Due to its special chemical structure, LUVOPLUS® DA 100 also has corrosion-inhibiting properties. |

LUVOTIX® - Organic rheology additives for solvent-based and solvent-free systems

LUVOTIX® rheology additives are fine, micronized waxes that are mainly made from renewable raw materials. The powders are based on castor oil derivatives, fatty acid amides and polyolefins.

Depending on the polarity of the system, the products are incorporated directly in powdered form in a time and temperature-controlled dispersing process. In addition to the standard types that have proven themselves and have been tested for many years, rheology additives that are particularly easy to activate are available. These develop their full effectiveness even at low temperatures after shearing.

| Products | Description | Application |

|---|---|---|

| LUVOTIX® R | Castor oil derivative | LUVOTIX® R controls the rheology properties of low to medium polar liquid organic systems. It is used as a thickener, thixotropic or anti-settling agent in paints and coatings, adhesives, sealants and putties as well as in oils. LUVOTIX® R is used as a flow and levelling agent in powder coatings. |

| LUVOTIX® R-RF | Castor oil derivative, inorganically modified | LUVOTIX® R-RF is used as a thickener and thixotropic agent in low to medium polar liquid organic systems. It is easy dispersible, improves the formulations workability and has been primarily developed for putties. |

| LUVOTIX® ZR 50 | Castor oil derivative, inorganically modified | LUVOTIX® ZR50 controls the rheology properties of low polar solvent-based and solvent-free formulations, specifically in highly filled coatings, putties and sealants. |

| LUVOTIX® HT | Castor oil derivative, polyamide-modified | LUVOTIX® HT controls the rheology properties of low to medium polar liquid organic systems. It is used as a thickener, thixotropic or anti-settling agent in paints and coatings, adhesives, sealants and putties as well as in oils. In powder coating formulations, LUVOTIX® HT serves as a levelling agent. |

| LUVOTIX® HT-SF | Castor oil derivative, polyamide-modified | LUVOTIX® HT-SF describes the same application profile as LUVOTIX® HT with an easier activation. |

| LUVOTIX® ZH 5 | Castor oil derivative, polyamide-modified, with inorganic content | LUVOTIX® ZH5 controls the rheology properties of medium to higher polar solvent-based formulations. The material is free-flowing, easily dispersible and particularly suitable for highly filled systems. |

| LUVOTIX® ZH 50 | Castor oil derivative, polyamide-modified, with inorganic content | LUVOTIX® ZH50 controls the rheology properties of medium to higher polar liquid organic systems, specifically in highly filled formulations. |

| LUVOTIX® HP | Polyamide | LUVOTIX® HP is used in solvent-based and solvent-free medium to higher polar liquid organic systems. It is suitable as a thickener, thixotropic or anti-settling-agent in paints and coatings, adhesives, sealants, putties and other formulations. |

| LUVOTIX® AB | Blend of polyamides | LUVOTIX® AB is used in solvent-based and solvent-free medium polar liquid organic systems. Its optimum performance is achieved at process temperatures between 50 and 65°C. It is suitable for highly filled and gloss systems. It is used in paints and coatings, adhesives as well as in sealants, putties and other formulations. |

| LUVOTIX® SAB | Blend of polyamides | LUVOTIX® SAB is suitable as a rheology additive for many applications in solvent-based and solvent-free formulations. Its optimum performance is achieved at process temperatures in the range of approx. 50-70°C, depending on the polarities in the formulation. LUVOTIX® SAB optimizes the sag-control and anti-settling properties and is particularly recommended for glossy acrylate or polyester based systems. |

| LUVOTIX® PAB | Blend of polyamides | LUVOTIX® PAB is used as a rheology additive in solvent-based and solvent-free medium to higher polar organic systems. Its optimum performance is achieved at process temperatures above 55°C. LUVOTIX® PAB can be used in primers as well as in glossy top-coat systems. It is suitable for industrial coatings, corrosion protection coatings, adhesives, putties and sealants. |

| LUVOTIX® P 100-15 | Polyolefin | LUVOTIX® P100-15 is used to modify the flow behavior in medium to higher polar solvent-based and solvent-free formulations, especially as an efficient anti-settling agent. |

| LUVOTIX® VP031 | Polyolefin/Stearic acid | LUVOTIX® VP031 is used in solvent-based and solvent-free high-build coatings., adhesives and sealants. Due to its physical-chemical properties, LUVOTIX® VP031 is particularly easy to incorporate and activate. |

| LUVOTIX® LT1 | Blend of polyamides | LUVOTIX® LT1 can be activated at very low process temperatures, starting at 40°C. It is used in paints and coatings, adhesives and sealants, putties and other formulations. |

| LUVOTIX® TK1 | 2-pack-rheology additive | LUVOTIX® TK1 is used in situ in combination with crosslinker LUVOTIX® CL1. It is suitable for all systems independent of polarity. In topcoats, it is characterized by high gloss and transparency combined with excellent anti-sag properties. |

| LUVOTIX® CL1 | Amino-functional crosslinker | LUVOTIX® CL1 is used as a crosslinker combined in situ with LUVOTIX® TK1 in a mixing ratio 30:100. |

| LUVOTIX® P25X | Polyolefin paste, 25 % in Xylene | LUVOTIX® P25X is used as an anti-settling and sag-control agent in solvent-based formulations. It improves stabilization in zinc-rich primers. |

| LUVOTIX® R400 | Castor oil derivate | LUVOTIX® R400 is used in powder coatings as process additive and flow modifier. |

| LUVOTIX® HT400 | Castor oil derivate, polyamide modified | LUVOTIX® HT400 is used in powder coatings as process additive and flow modifier. |

LUVOGEL® - Inorganic rheology additives for solvent-based and water-based systems

Naturally occurring and organically modified phyllosilicates from the LUVOGEL® series are used in water-based and solvent-based systems for rheology control. The powdered additives are incorporated directly at the beginning of the dispersing process or in form of pre-gels. Polar chemical activators are sometimes added to increase gel formation in solvent-based systems. Easily dispersible and self-activating LUVOGEL® additives enable fast and successful activation processes without the necessity to control the temperature.

| Products | Description | Application |

|---|---|---|

| LUVOGEL® 4 | Montmorillonite, organically modified | LUVOGEL® 4 is used as an anti-settling and sag-control agent in low to medium polar formulations such as industrial coatings, do-it-yourself-coatings, construction paints, primers, printing inks, adhesives and putties. The addition of a polar activator is recommended. |

| LUVOGEL® 4 B | Montmorillonite, organically modified | Compare LUVOGEL® 4 – LUVOGEL® 4B contains higher amount of organic component. |

| LUVOGEL® 7 | Montmorillonite, organically modified | LUVOGEL® 7 is used as an anti-settling and sag-control agent in low to medium polar formulations such as industrial coatings, do-it-yourself-coatings, construction paints, primers and printing inks. The addition of a polar activator is recommended. |

| LUVOGEL® SA 1 | Montmorillonite, organically modified | LUVOGEL® SA1 is used as a self-activating anti-settling agent and rheology additive in solvent-based formulations of a wide polarity range, e.g. in industrial coatings, DIY paints, architectural paints, primers or printing inks. |

| LUVOGEL® SA 10 | Montmorillonite, organically modified | LUVOGEL® SA10 is used as an anti-settling and sag-control agent in low polar aliphatic formulations. |

| LUVOGEL® ED | Montmorillonite, organically modified | LUVOGEL® ED creates a shear thinning flow profile with thixotropic properties and a slight viscosity increase in formulations. |

| LUVOGEL® G58 | Layered silicate, organically modified | LUVOGEL® G58 is mainly used as a rheological and anti-settle additive in unsaturated polyester resins, epoxy resins and vinyl esters, especially in styrene-containing and solvent-containing formulations of different polarity, but also in solvent-free epoxy resin systems. |

LUVOTIX® - Organic rheology additives for water-based systems

LUVOTIX® ATAC are synthetic associative thickeners for water-based formulations, which are supplied as low-viscous acrylic emulsions. The anionic polymers develop viscosity after neutralization in the pH-range from 7.0 to 10.0.

Different shear-thinning rheological profiles can be achieved depending on the hydrophobic modifications of the molecules.

| Products | Description | Application |

|---|---|---|

| LUVOTIX® ATAC L 100 | Hydophobically-modified associative thickener based on HASE | LUVOTIX® ATAC L 100 is a hydrophobically-modified associative thickener used in waterborne adhesives, sealants, paints and coatings to improve both storage stability and sag resistance and settling behavior. LUVOTIX® ATAC L 100 produces a highly pseudoplastic flow profile in waterborne formulations and is particularly recommended to increase viscosity in the low to medium shear range. |

| LUVOTIX® ATAC M 400 | Non-associative thickener, based on ASE | LUVOTIX® ATAC M 400 is a VOC-free non-associative thickener for waterborne formulations and is used in paints, coatings as well as sealants and adhesives to improve color acceptance and wet abrasion. LUVOTIX® ATAC M 400 produces a highly pseudoplastic flow profile in waterborne formulations and is particularly recommended to increase the viscosity in all shear ranges. |

| LUVOTIX® ATAC H 700 | Hydophobically-modified associative thickener based on HASE | LUVOTIX® ATAC H 700 is a hydrophobically-modified anionic thickener for waterborne adhesives, sealants, paints, lacquers, and protective coatings. Use of LUVOTIX® ATAC H 700 improves the storage stability, levelling, and anti-splash system properties. LUVOTIX® ATAC H 700 produces a Newtonian flow profile in waterborne formulations and is particularly recommended to increase the viscosity in the high shear range. |

LUVOTIX® ATUR are non-ionic hydrophobically modified polyurethanes used in water-based formulations, independent of pH-range. By tailored modifications of molecular structures, any desired rheological profile from newtonian to strong shear thinning can be obtained. LUVOTIX® ATUR are specifically designed for glossy, high-quality coatings when excellent surface levelling properties are desired after application.

| Products | Description | Application |

|---|---|---|

| LUVOTIX® ATUR L 200 | Hydophobically-modified polyurethane thickener based on HEUR | LUVOTIX® ATUR L 200 is a hydrophobically-modified biobased polyurethane thickener. LUVOTIX® ATUR L 200 is used in waterborneadhesives, sealants, and paints and coatings and improves the rub-out resistance, storage stability and chemical/water resistance. LUVOTIX® ATUR L 200 is APEO- and VOC- free and is particularly recommended to increase viscosity in the low shear range. |

| LUVOTIX® ATUR M 500 | Hydophobically-modified polyurethane thickener based on HEUR | LUVOTIX® ATUR M 500 is a hydrophobically modified polyurethane thickener for waterborne adhesives, sealants, paints, lacquers and protective coatings that improves the levelling, spraying and sag resistance of waterborne formulations. LUVOTIX® ATUR M 500 has a pseudoplastic flow behavior and is particularly recommended for increasing viscosity in the medium shear rate range. |

| LUVOTIX® ATUR M 510 | Hydophobically-modified polyurethane thickener based on HEUR | LUVOTIX® ATUR M 510 is a hydrophobically-modified polyurethane thickener for waterborne adhesives, sealants, paints, lacquers, and protective coatings that improves levelling, spraying and sag resistance. LUVOTIX® ATUR M 510 has a pseudoplastic flow behavior and is particularly recommended to increase viscosity in the medium shear range. |

| LUVOTIX® ATUR M 600 | Hydophobically-modified polyurethane thickener based on HEUR | LUVOTIX® ATUR M 600 is a hydrophobically-modified polyurethane thickener for waterborne adhesives, sealants, paints, and coatings that improves levelling, settling and sagging of waterborne formulations. LUVOTIX® ATUR M 600 has a pseudoplastic flow behavior and is particularly recommended to increase viscosity in the medium shear range. |

| LUVOTIX® ATUR H 800 | Hydophobically-modified polyurethane thickener based on HEUR | LUVOTIX® ATUR H 800 is a hydrophobically-modified polyurethane thickener for waterborne formulations, used in adhesives, sealants, paints, lacquers, and protective coatings to improve properties such as levelling, wet abrasion, and film formation. LUVOTIX® ATUR H 800 has a Newtonian flow behavior and is particularly recommended to increase viscosity in the high shear range. LUVOTIX® ATUR H 800 can be effectively combined with LUVOTIX® ATUR L 200. |

LUVOGEL® - Inorganic rheology additives for solvent-based and water-based systems

Naturally occurring and organically modified phyllosilicates from the LUVOGEL® series are used in water-based and solvent-based systems for rheology control. The powdered additives are incorporated directly at the beginning of the dispersing process or in form of pre-gels. Polar chemical activators are sometimes added to increase gel formation in solvent-based systems. Easily dispersible and self-activating LUVOGEL® additives enable fast and successful activation processes without the necessity to control the temperature.

| Products | Description | Application |

|---|---|---|

| LUVOGEL® W1 | Montmorillonite

| LUVOGEL® W1 is used in water-based formulations, e.g. adhesives, paints and coatings, cleaning agents, polishes, etc. It produces a pseudoplastic flow profile with thixotropic properties and improves settling behavior and flow control. |

| LUVOGEL® W3 | Montmorillonite

| LUVOGEL® W3 is used in water-based formulations, e.g. adhesives, paints and coatings, cleaning agents, polishes, etc. It produces a pseudoplastic flow profile with thixotropic properties and improves settling behavior and flow control. |

| LUVOGEL® AQ | Synthetic Hectorite | LUVOGEL® AQ is mainly used as a rheological additive in water-based formulations. The main areas of application are industrial coatings and automotive paints – OEM as well as After-Market. The products provide excellent stabilisation and orientation of effect pigments. |

| LUVOGEL® W2N | Synthetic Hectorite | LUVOGEL® W2N is mainly used as a rheological additive in water-based formulations. The main areas of application are industrial coatings and automotive paints – OEM as well as After-Market. The products provide excellent stabilisation and orientation of effect pigments. |

| LUVOGEL® WS1 | Synthetic Hectorite | LUVOGEL® WS1 is a synthetic smectite clay modified by an inorganic sodium phosphate. It is used as a rheological additive in water-based formulations. |

| LUVOGEL® WS2 | Synthetic Hectorite | LUVOGEL® WS2 is a synthetic smectite clay modified by an inorganic sodium phosphate. It is used as a rheological additive in water-based formulations. |

WOLLATROP® - Inorganic rheology additives for water-based systems

WOLLATROP® are hydrated and inverted ribbon silicates that are used as inorganic thickeners in water-based systems. The additives are particularly easy to incorporate into formulations thanks to their filamentous and flexible structure. Unlike classic phyllosilicates, WOLLATROP® products develop a stable structure immediately after incorporation, which leads to increased viscosity, especially in the low shear rate range. WOLLATROP® products are characterized by a high tolerance to changes in ionic strength and pH fluctuations.

| Product | Description | Application |

|---|---|---|

| WOLLATROP®-S | Ribbon silicates with fine fiber distribution | Preferred use in paints, varnishes and coatings. |

| WOLLATROP®-SE | Ribbon silicates with fine fiber distribution | Preferred use in paints, varnishes and coatings. |

| WOLLATROP®-M | Absorbent filler based on ribbon silicates | Application as rheology additive in construction chemical products such as mortars, construction and tile adhesives, fillers and filling compounds, but also high build coatings and wall or facade paints. Particularly suitable for use at high temperature. |

| WOLLATROP®-LV | Silicate fibers, organically modified | Preferred use in water-based coatings with low to medium layer thickness as well as in construction chemical products, such as adhesives or plasters. |

| WOLLATROP®-S/240 | Silicate hybrid | WOLLATROP®-S/240 is an economical rheology additive. It can be used as a multifunctional rheology additive in construction chemical products or high build coatings that require micro-reinforcement or crack bridging in addition to rheological adjustment. |

Video Surface Technology (Oberflächentechnik)

Please accept the External Content Cookie option if you want to play this video. Please note: Once you watch the video, data will be transmitted to Youtube/Google. For more information, see Google Privacy.

Your personal contact